When Polytec expands its portfolio, the new product line must not only be of high quality, mature, and state-of-the-art, but also convincing in terms of the future viability of the technology used.

A good example of this is the OmniCure® product line from Excelitas Technologies, which includes a wide range of light sources for industrial UV curing. The systems are designed for UV curing in point, line, and area applications – featuring both intelligent UV medium-pressure lamps and cutting-edge LED technology.

UV curing of a wide variety of materials has been established for decades. OmniCure® intelligent UV medium-pressure lamps deliver highly precise and repeatable light output. Modern LED light sources, on the other hand, offer longer lifetimes, lower maintenance requirements, and significant environmental benefits. These advantages stem from considerably lower energy consumption and the fact that the lamps contain no mercury and produce no ozone during operation. As a result, operating costs are also reduced. The applications vary widely due to the broad range of available products.

Medical devices

In the production and use of medical devices, features such as closed-loop feedback, precise irradiation control, and wavelength selection of the UV source play a crucial role. They enable manufacturers to achieve a controlled and highly repeatable production process, as well as strict process control of critical parameters such as delivered optical energy, product temperature, and spectral content. UV curing systems are used, for example, in the production of catheters, cannulas, and endoscopes, as well as hearing aids and anesthesia masks. LED solutions are becoming increasingly important in the manufacture of hydrogels for medical electrodes, such as those used in ECG examinations.

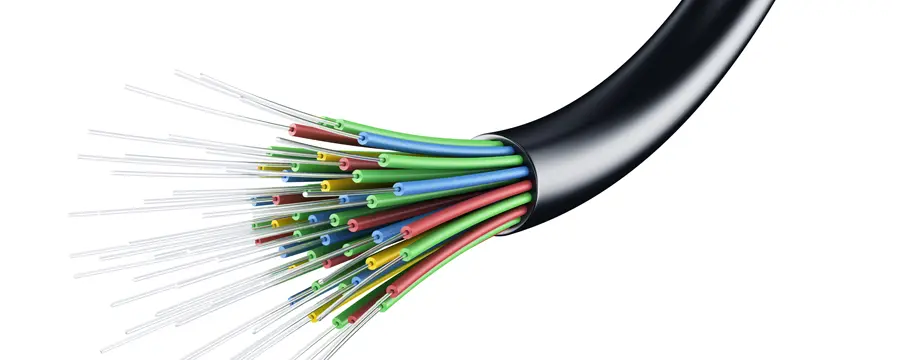

Fiber coatings

Fiber-based telecommunications is a rapidly growing market. Corresponding fibers are produced in so-called draw towers, which can reach heights of several stories and production speeds of 2,000 meters per minute. During manufacturing, the fibers are coated with multiple polymer layers, which are cured using UV light. The production speed gives an idea of how powerful and precise the irradiation must be to ensure uniformly coated fibers. It is no wonder that a dedicated OmniCure® system was developed for this application.

Electronics & optoelectronics

The production of electronic and optoelectronic components benefits from UV curing systems that ensure the highest precision and repeatability – a prerequisite for achieving the throughput and yields required for high-volume automated processes. The range of applications is very broad and extends far beyond examples such as coatings and adhesives in chip, display, and component production or fiber-optic component

Assembly, placement, and coating

The use of UV-curable adhesives is becoming an increasingly important assembly technique due to their fast processing, easy automation, low energy requirements, and solvent-free bonding. UV curing can be used to bond stainless steel, glass, ceramics, rubber, a wide variety of plastics, and other materials, or for diamond mounting. Spot curing systems are primarily used for these applications.

Digital printing

UV curing or drying of digitally printed codes, labels, product markings, or serial numbers is an established practice. Modern LED curing systems improve print quality by reducing heat exposure to the substrate, as LED light is concentrated within a narrower spectral range than conventional light sources. This also enables printing on heat-sensitive substrates. Operating costs are reduced thanks to a tenfold longer service life and lower maintenance requirements compared to arc lamps.