Coherence Scanning Interferometry (CSI)

Coherence Scanning Interferometry (CSI, a type of white-light interferometer), is a highly effective technique for measuring surface roughness, owing to its non-contact nature, data clarity, high precision, and ability to capture both smooth and rough surface textures. It employs a broadband light source to generate interference patterns, which are used to determine surface heights down to the sub-nanometer scale. This capability is particularly valuable throughout many industry sectors like; semiconductor manufacturing, precision optics, automotive, medical, aerospace and material science, where surface quality is critical.

Broadband light and surface coverage

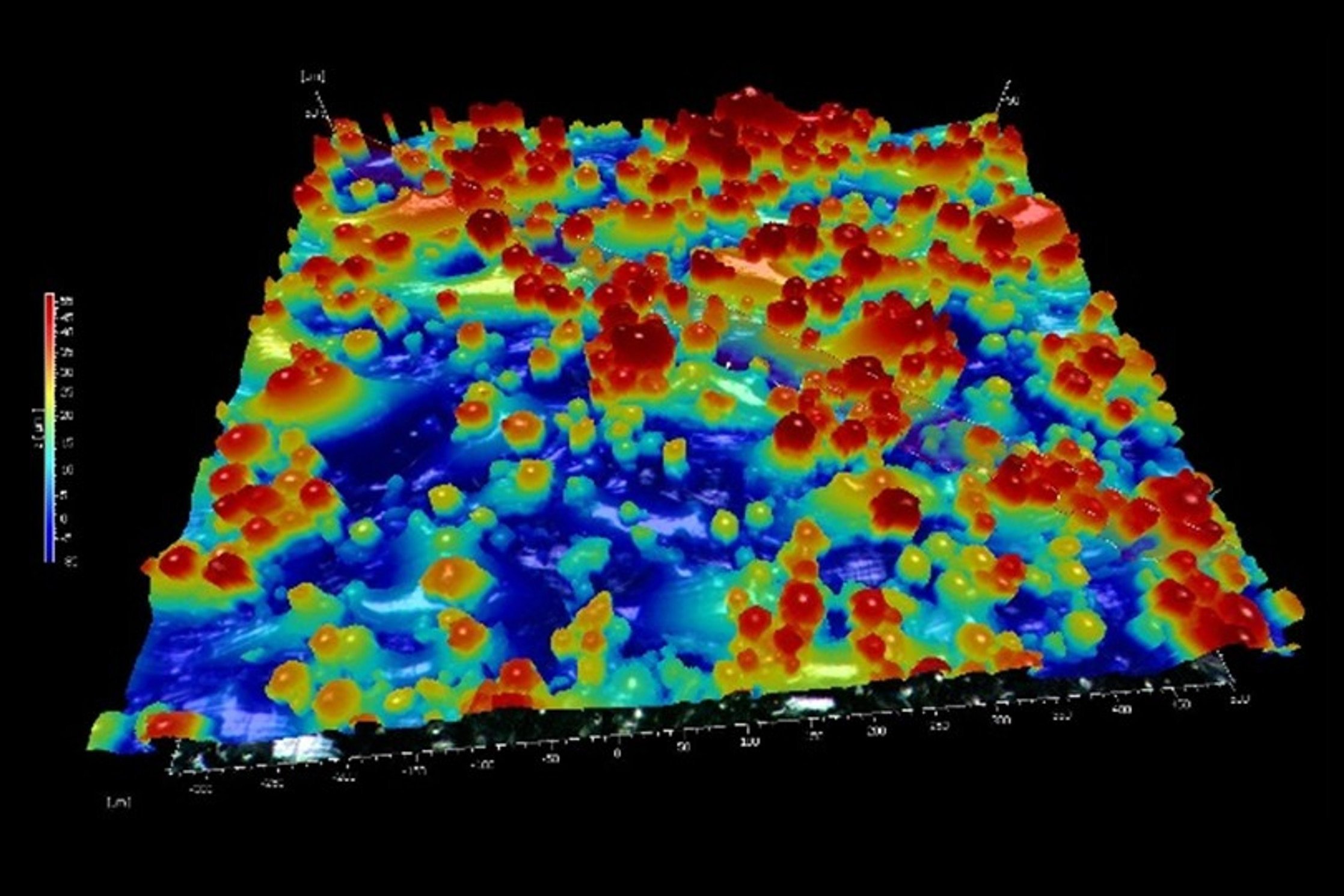

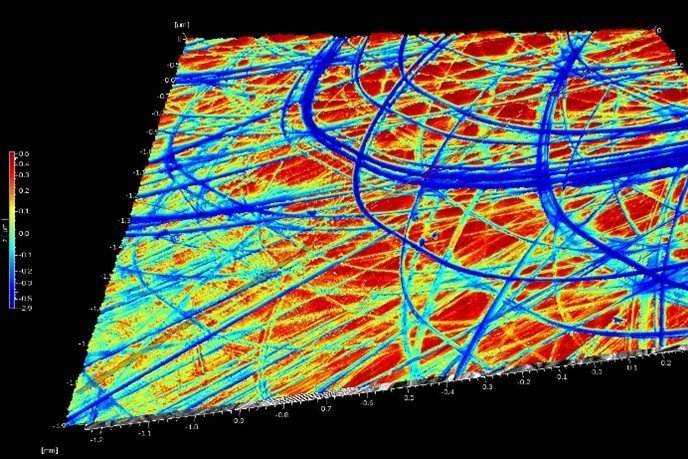

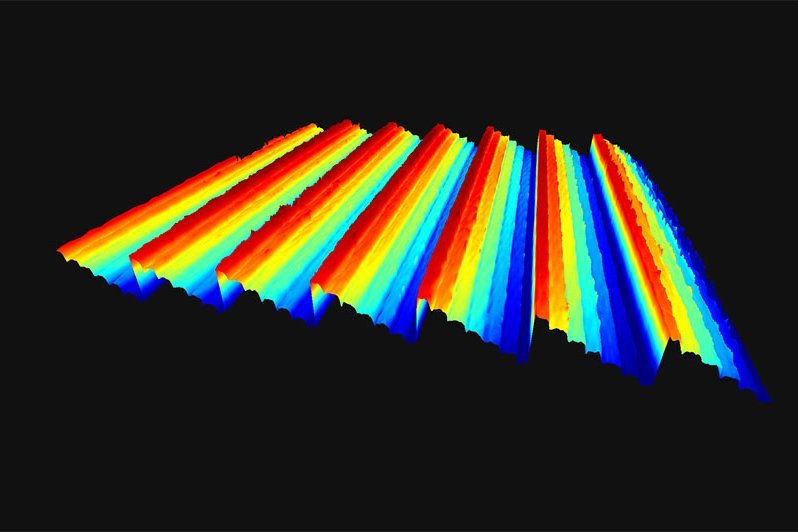

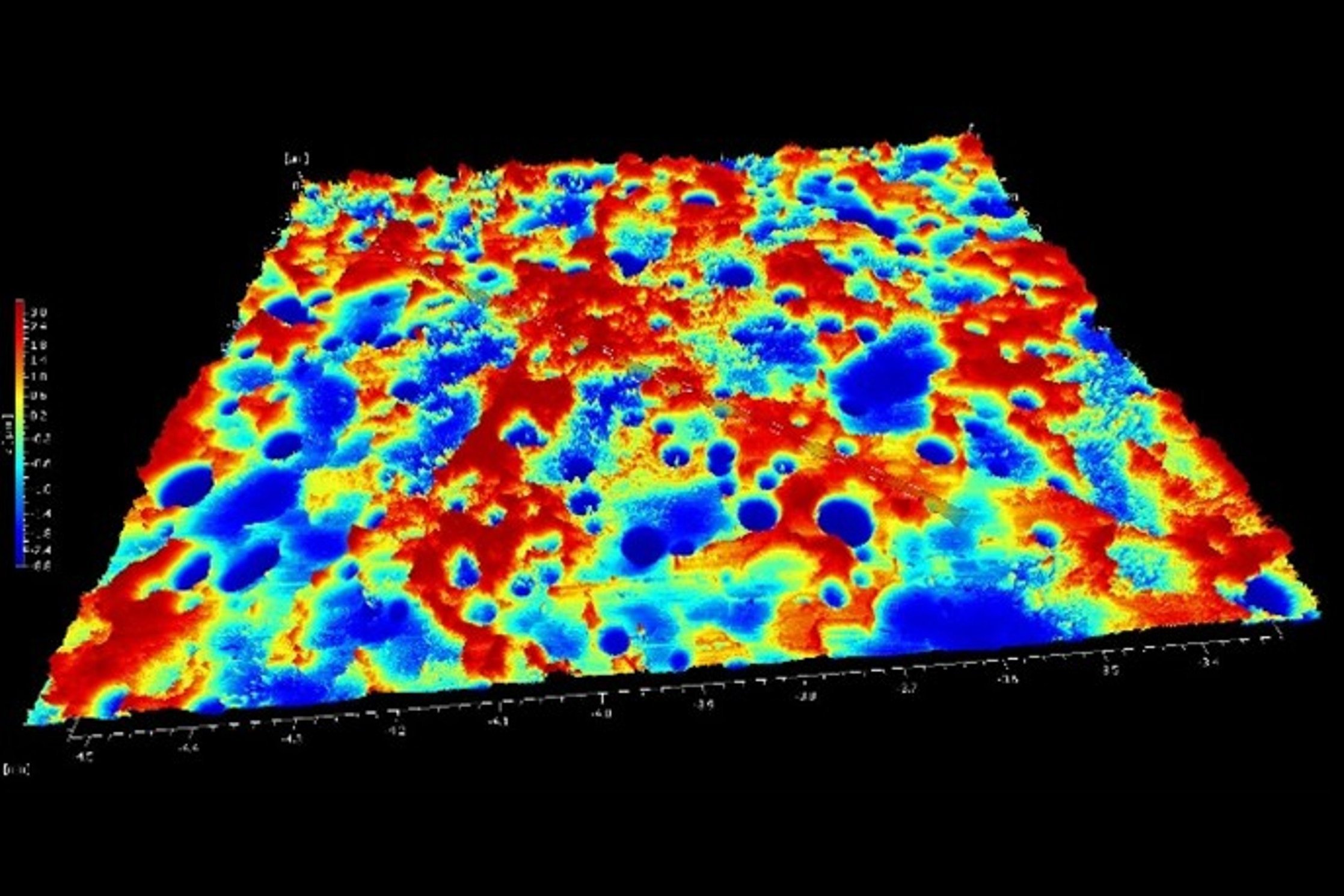

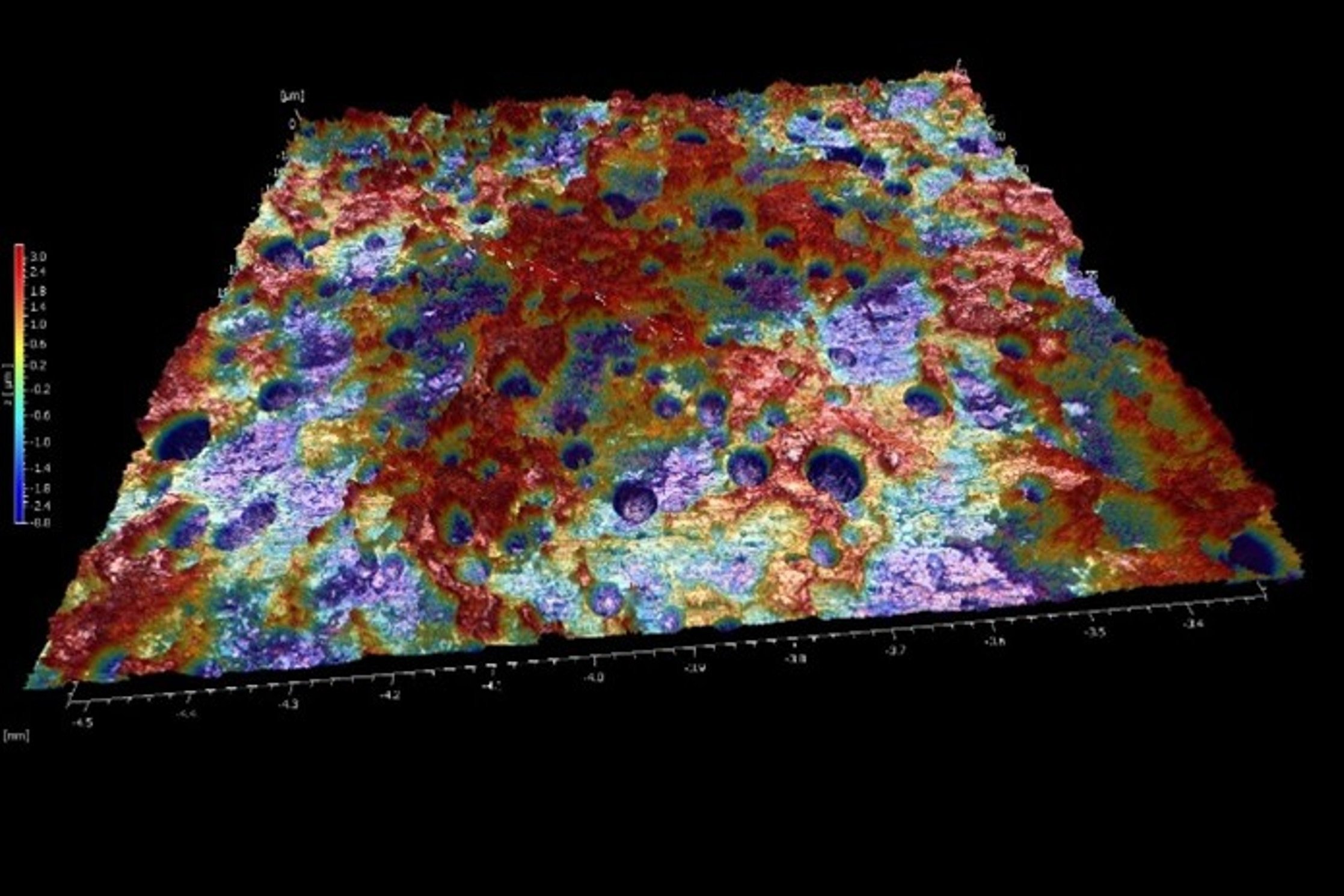

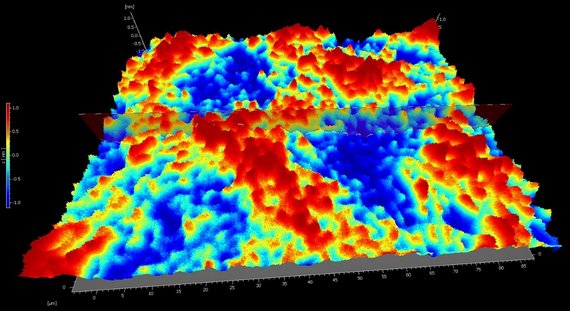

The use of white-light, consisting of a broad range of wavelengths (for Polytec central wavelength band is 525nm), a Coherence Scanning Interferometer as optical profiler can be used to thouroughly measure a wide variety of surface features: For smooth surfaces, CSI detect minute deviations in height with nanometer-level accuracy. On rough surfaces, the broadband nature of white-light ensures that the profiler can still distinguish small details with clarity, even when the surface consists of larger, irregular features. This broad wavelength range enables Coherence Scanning Interferometers to accommodate the full spectrum of surface roughness, from smooth, polished surfaces to those with significant texture variations, for example; surface peening or additive manufactured surfaces.

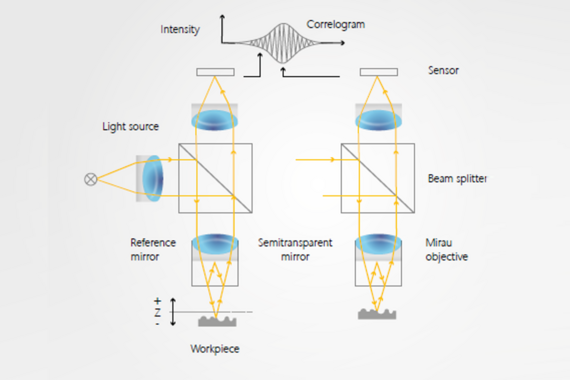

Working principle of Coherence Scanning Interferometry

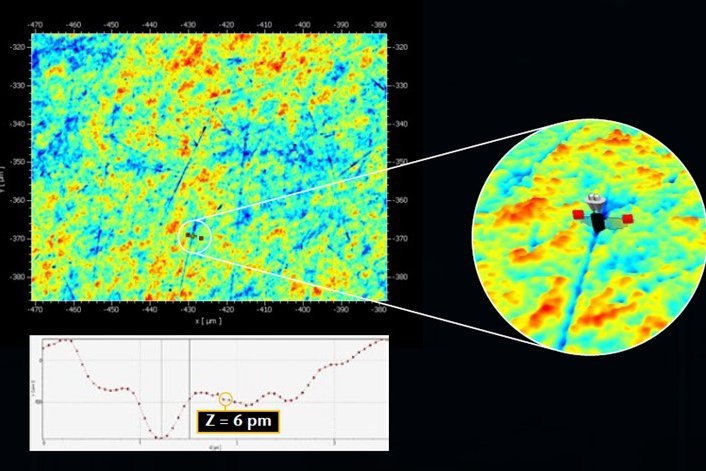

In a Coherence Scanning Interferometry optical profiler, white-light passes through a beam splitter, which directs the light to both a sample surface and to a reference mirror. When the light reflects back from these two surfaces, it is recombined, and a pattern of interference “fringes” forms. Maximum fringe contrast occurs at the best focus position for each point on the sample. Either the test sample or the measurement head is scanned/ translated vertically (Z direction) in such a way that each individual camera pixel point on the surface passes through focus. In general, a math algorithm is applied. It should be noted that the better the math, the greater the clarity of the focus can be defined. For Polytec as Coherence Scanning Interferometry specialist, they have a math algorithm called the “correlogram”. This correlogram signal processing algorithm uses the interference signals to find the best/ sharpest focus point, operating beyond the diffraction barrier of light to provide sub-nanometer Z sensitivity.

High Z sensitivity with large Z range

When using this CSI driven correlogram algorithm with a long-scanning mechanical setup, this possibility enables high Z sensitivity to be applied over large Z-translation ranges, while maintaining good noise performance and high surface sensitivity irrespective of long or short scanning range. The series of data sampling collected can precisely map the height of each surface point with sub – nanometer resolution over the full Z scan range with no sacrifice of range to resolution limit, other than that of the working distance of the interferometric lens (up to 30 mm). Polytec refers to this approach as its CST Continuous Scanning Technology. All data is deterministic in Z in nature (not focus driven via different lens options) and always has good noise performance and clarity of surface information.

This CST Continuous Scanning Technolgy and data processing allow for precise measurements even in the presence of super smooth, rough or irregular surface textures and combinations.

Measure on difficult surface materials

The ability of CSI to handle a broad range of surface textures is further enhanced by its ability to automatically adjust to different surface characteristics. This makes it highly versatile for applications requiring measurements across different types of materials, whether metals, ceramics, glass, silicon, paper or polymers, with varying degrees of roughness, contrast and reflectivity. Reflectivity performance is from 0.05% to 100%.

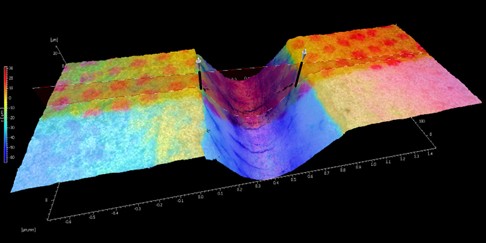

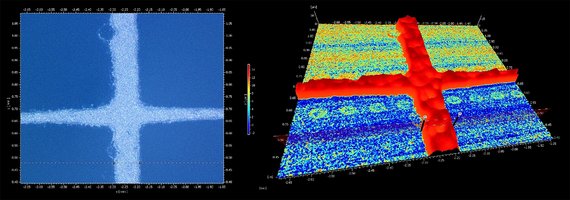

Comprehensive 3D surface data

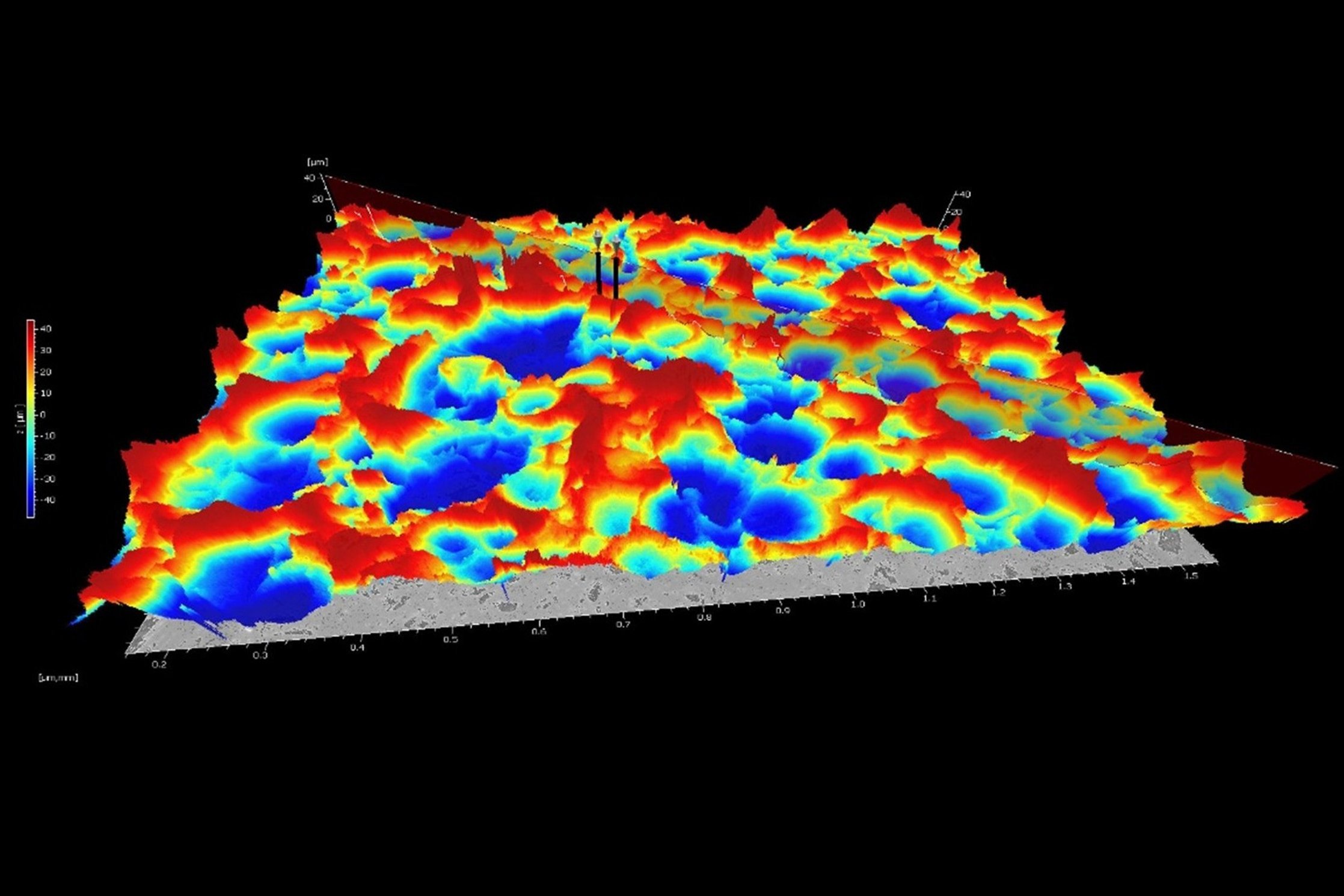

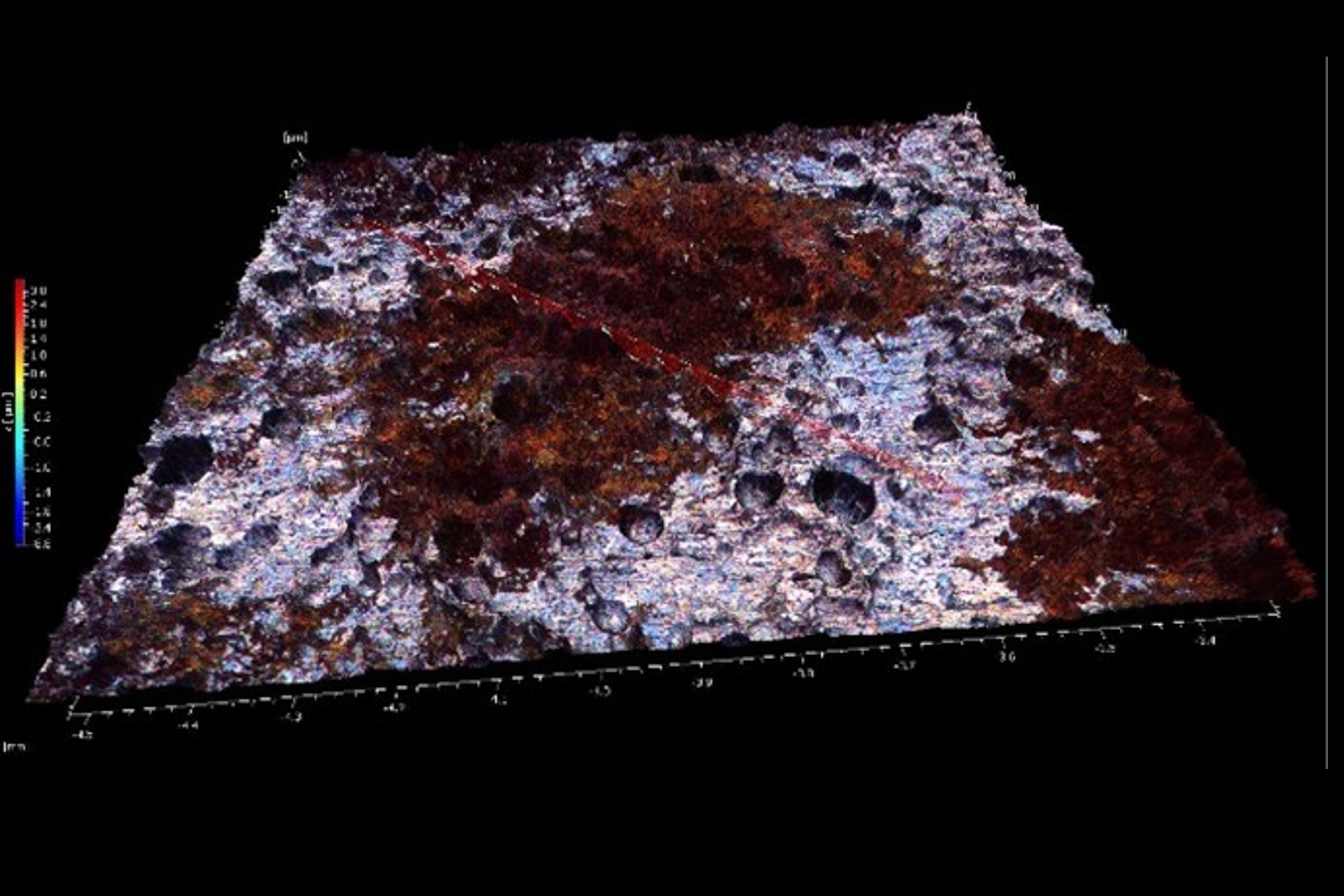

Unlike traditional 2D profilometry methods, CSI provides comprehensive three-dimensional surface data. By capturing detailed height information across the entire surface, it allows for a more complete analysis of surface roughness. The resulting 3D maps enable engineers and scientists to assess the overall texture and uniformity of the surface, which is essential for applications requiring precise control of surface quality, such as in optical lenses, coatings, and microelectronics.

Color surface imaging reveals surface details that would be difficult to see. People like to see 3D height color maps or with a vivid graphic representation for enhanced viewing and reliable numerical representation in order to getting…

The Answer of A Surface