Climate change is one of the dominating challenges of modern society and industry. Even though steel is one of the worlds most recycled materials, the steel industry remains the largest industrial emitter of carbon dioxide. For more sustainability and responsible manufacturing, ProSpeed® Laser Surface Velocimeters can assist in process control and enhance efficiency in industrial manufacturing: precise measurement and process control leads to less scrap or waste by improving e.g. cut-to-length control in processes such as continuous casting and plate production.

For globally operating companies the topic of sustainable and ecological-responsible manufacturing is becoming increasingly important. With increasing attention from customers, governments, legal aspects, social organizations, society just to name a few. This is the point where environmental sustainability of an organization is linked to its economic sustainability as a functioning long-term business model can only sustain when those factors are considered seriously. Especially when operating in areas of greater environmental awareness such as Europe or the United States of America.

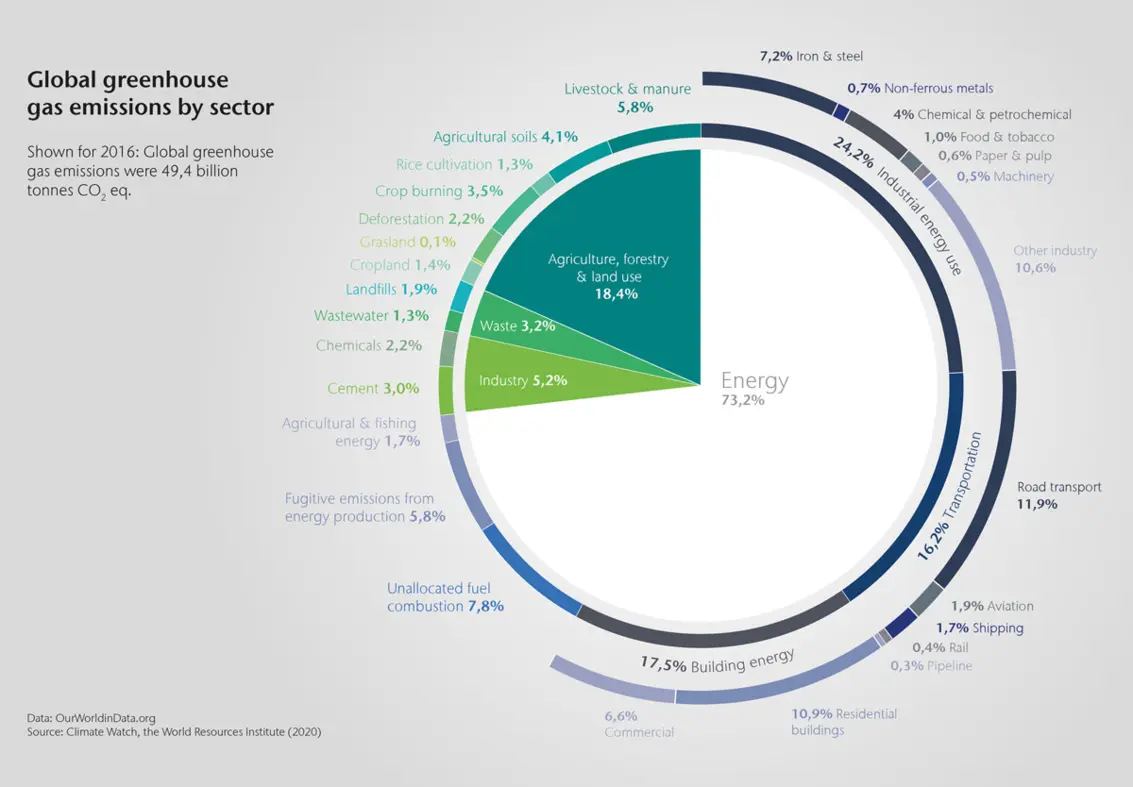

According to the World Steel Association roughly 7 % to 9 % of the entire global CO2 emissions are directly related to the production of steel.1 This results in around one third of the total emissions generated worldwide, in all industries combined.2

The World Steel Association, which represents more than 80 % of global steel production, agreed on a program called “Step Up” in order to address specific actions aiming in the direction of improving the steel industries sustainability impacts.3

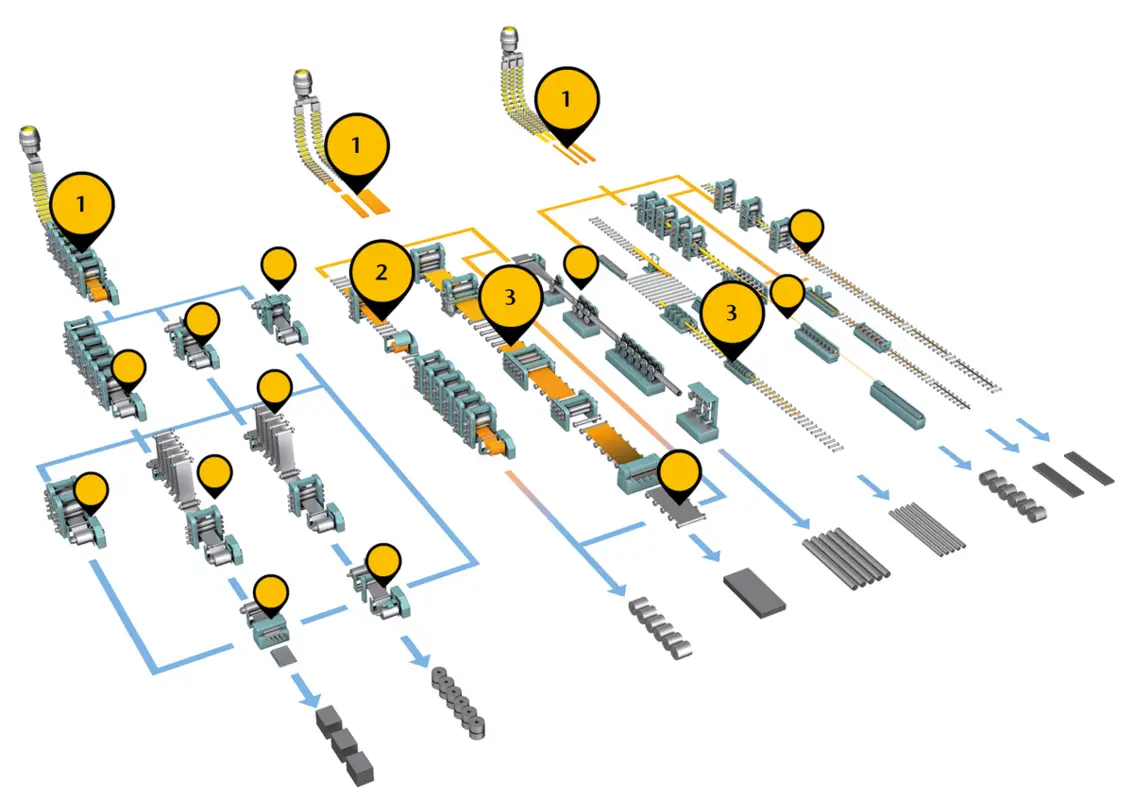

Process optimization and production efficiency has big paybacks in improved throughput, reduced scrap and increased yield and has the added benefit of reducing the carbon footprint. Many specific factors are involved from process to process, but length & speed measurement can be found in nearly all processes from the caster on. In addition, optimizing length measurements in one process not only aids that process but often reduces scrap and improves yield in the following processes and resulting products.

- Precise control of the cut length on continuous casters (no. 1)

- Crop-optimization in hot strip mills (no. 2)

- Reliable control of throughput times at reheating furnaces (no. 3)

Furthermore, precise speed information can also be used as a control variable in many processes, which can lead to significant improvements in the quality of the end products and stabilize the processes.

ProSpeed® laser sensors in steel industry

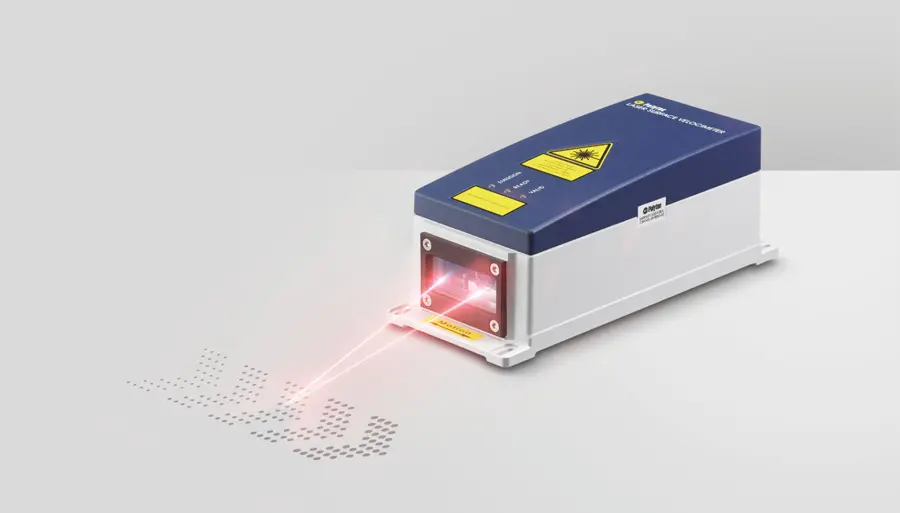

ProSpeed® – the next generation LSV Laser Surface Velocimeters – optimize production processes by providing reliable measurements and increase the output worldwide in the metals, cable and converting industries. The ProSpeed® LSV-1100 optical sensor measures the movement of the produced goods with laser precision. It measures reliably even under harsh production conditions with working distances up to 1.5 m. Due to the non-contact measurement principle, these laser sensors eliminate common problems of traditional contact-wheel measurement methods such as damage to delicate surfaces, slippage and thermal expansion and work on almost any surface.

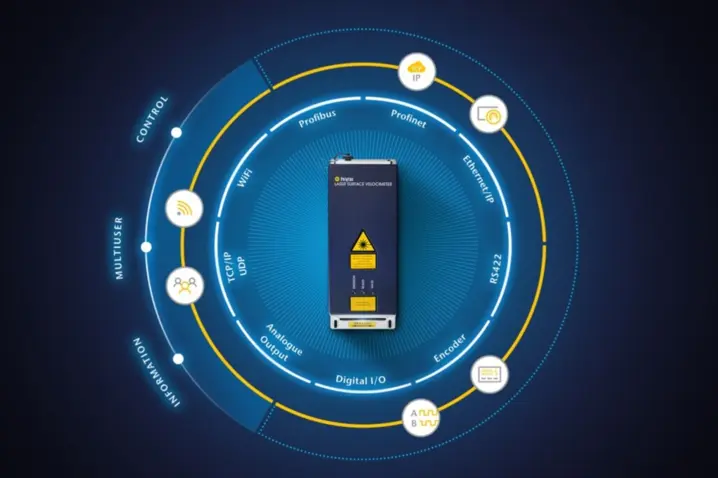

Sensor integration and control with enhanced connectivity

The enhanced connectivity of the next generation sensor ProSpeed® LSV-1100 provides access to configuration and process data – anywhere and anytime. Increase your flexibility and get direct feedback through touch display. Comfortably parametrize via web interface and allow concurrent data access for up to four parallel users.

For automated PLC-controlled processes the integrated PROFINET and EtherNet/IP interfaces allow an easy integration of the sensors into production control systems.