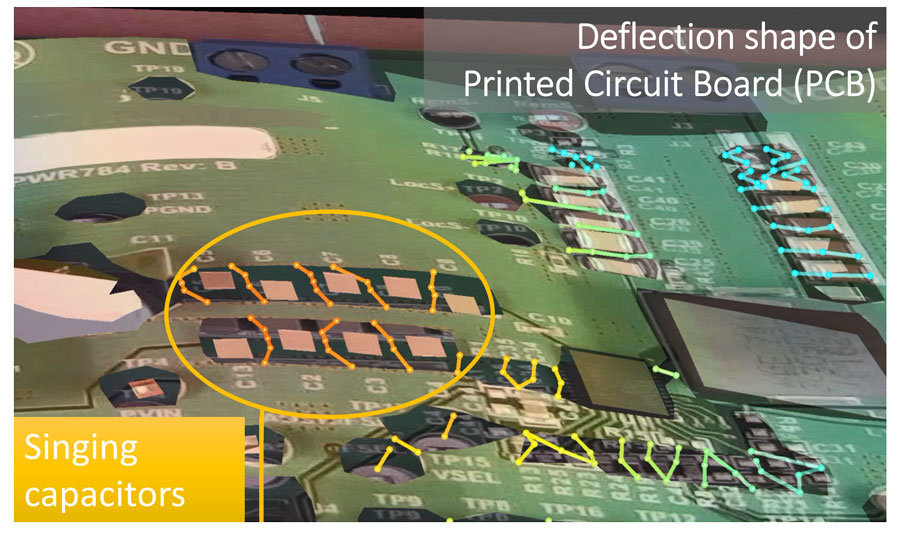

Everybody enjoys good sound quality on a mobile device when watching a show or when communicating with friends and family or in a business environment. On the other hand, we cringe when something is off with the audio. One of the culprits of poor sound quality is the singing capacitor, a term that has been widely adopted in the industry. A capacitor starts ‘singing’ when the ripple current on the input signal causes the capacitor to vibrate due to the piezoelectric effect. The acoustic noise is not directly caused by the vibrating capacitor, but rather indirectly, when the capacitor causes the printed circuit board (PCB) to vibrate.

How can this phenomenon of a singing capacitor be characterized? How can the design engineer choose the right capacitor for a specific application and adjust the board layout to avoid a singing capacitor situation? Conventional microphones measure sound pressure level (SPL), however, they lack spatial resolution and are therefore incapable of identifying the culprit (i.e. the capacitor that is causing the PCB to sing). The vibration amplitudes of singing capacitors are very small. Even sub-nanometer displacements cause the PCB to vibrate at sufficiently high levels to affect the audio experience of the consumer.

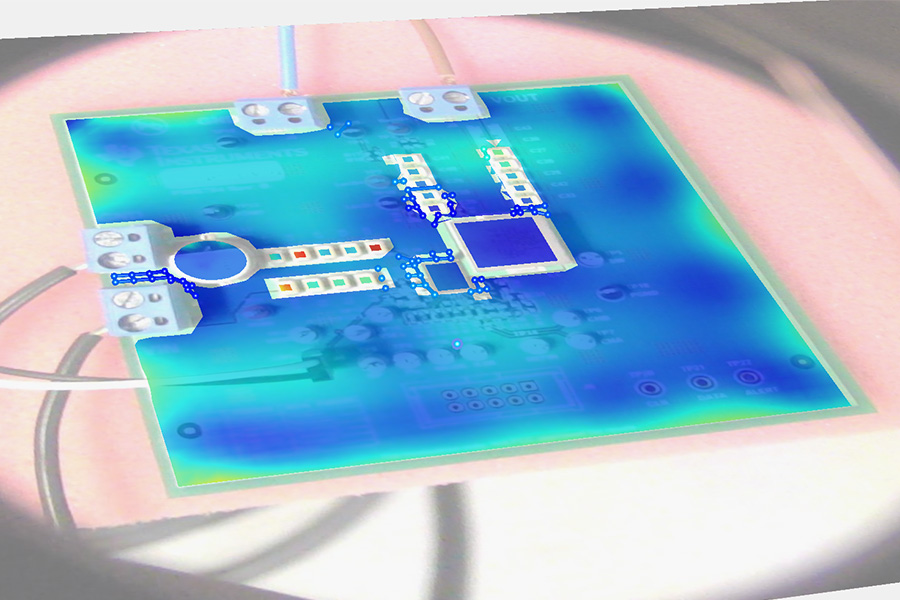

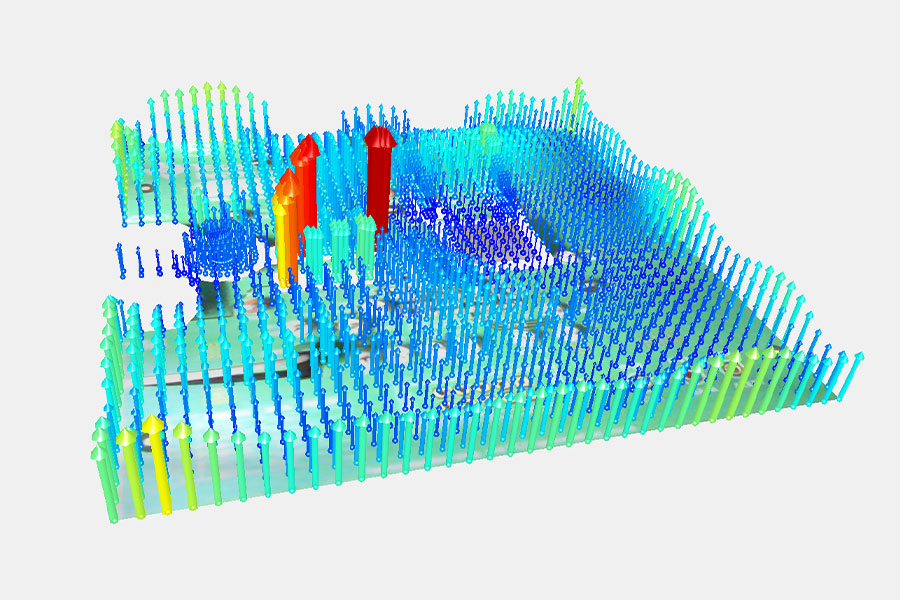

Operating deflection shape analysis revealing critical frequencies

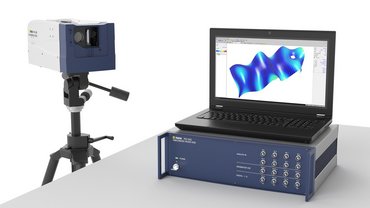

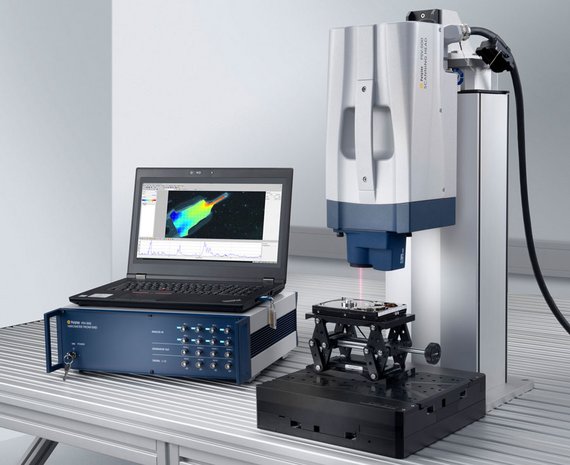

This is where Polytec’s laser Doppler vibrometers (LDVs) come in. A laser vibrometer is an optical sensor using a laser light for detecting even the slightest movement of an object’s surface, resolving vibration levels down to the picometer range.

The LDV acts like an ultra-high sensitivity optical microphone with a laser spot that is orders of magnitudes smaller than the size of the capacitor. Smart scanning mirrors inside the vibrometer head of a PSV Polytec Scanning Vibrometer allow product development engineers to characterize the PCB and its components accurately and quickly.

The vibration data is used in validating simulation models and performing troubleshooting tasks.

This animation demonstrates a nice example of a high density vibration scan on a PCB. From the data, the relationship in vibration response between PCB and capacitors is analyzed and the singing capacitor identified. Polytec vibrometers are highly valuable instruments in an development engineer’s tool box. Polytec vibrometer are used not only in consumer electronics, but also in the aerospace, automotive and medical industry as well as in the development of ultrasonic transducers and MEMS.

Images courtesy: Images courtesy of the authors unless otherwise specified. Cover image: Photograph: Jacob Lund/shutterstock.com & Waves: Kryshtofor Volodymyr