光学抛光如何提升表面质量

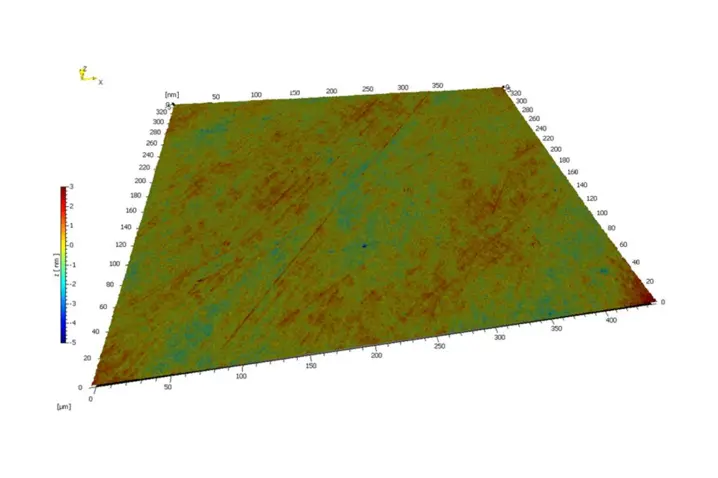

光学抛光是一种专门为实现最小缺陷和良好微观粗糙度而研发的制造技术。抛光过程采用游离磨粒,通常悬浮在液体(研磨液)中,而非像磨削那样将磨粒结合在砂轮上。该工艺可制造出粗糙度低于 1 Å的超光滑表面,能将散射光降至 1ppm(百万分之一)以下。

高精度光学元件由玻璃、金属等多种材料制成,需经抛光处理以满足光学表面光洁度要求。光学抛光卓越的表面精加工能力,使其被广泛应用于精密机械和光学元件的制造。

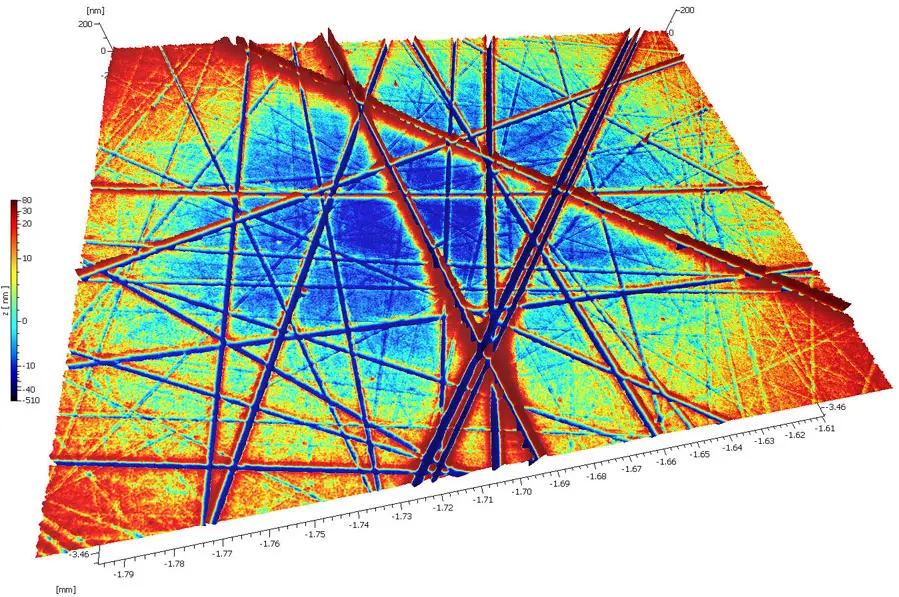

各制造商在这一基础抛光方法上会有细微差异,并拥有实现特定目标的专有技术。例如,不同材料在不同主轴转速或研磨盘转速下表现不同;流经光学表面的研磨液中,细小磨粒的尺寸一致性如何;抛光时间会对工艺产生何种影响;较大颗粒或外部污染物是否会造成表面划痕或损伤。

因此,密切关注抛光过程的各个环节至关重要。从工件搬运、主轴/研磨盘转速、研磨液中磨粒尺寸分布、抛光时间、电荷,到研磨液实际化学性质的监测,所有因素都会影响最终表面的质量。要持续制造出超光滑表面,难度极大。

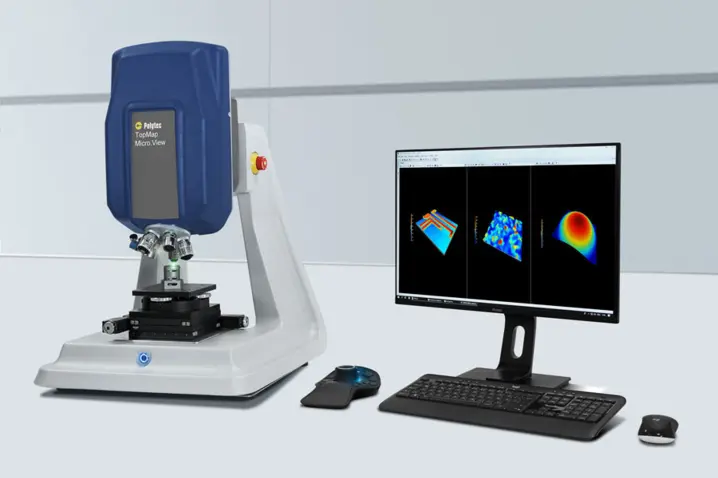

采用 TopMap Micro.View® 进行光学 3D 表面轮廓测量

TopMap Micro.View® 是德国 Polytec GmbH 公司推出的一款非接触式光学测量工具。它是一款极为先进的测量设备,融合创新技术与稳定可靠的测量能力,可依据国际标准和可溯源标准件对表面进行测量与表征。

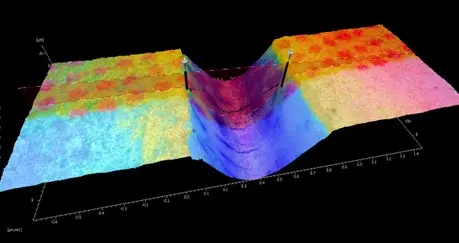

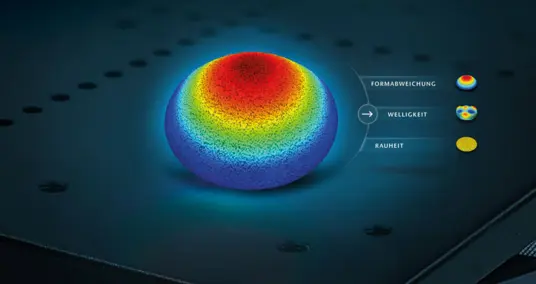

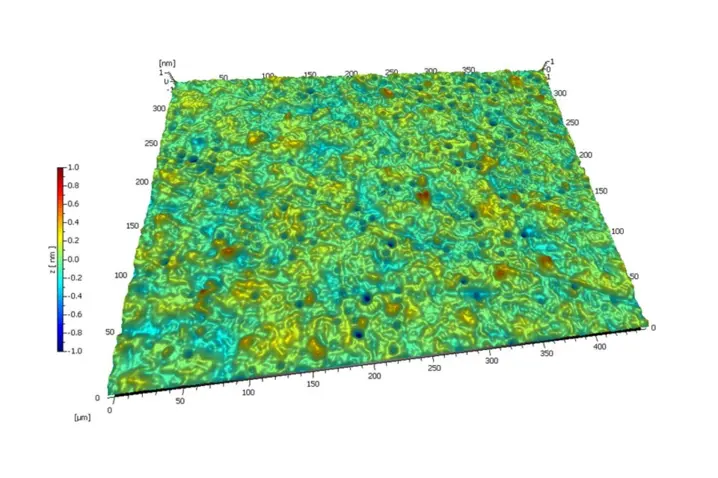

光学行业对质量控制的高要求,需要对超精加工表面纹理进行非接触式 3D 形貌检测。这款相干扫描干涉仪(CSI)除具备亚纳米级灵敏 Z 轴分辨率外,还拥有极高的测量重复性。结合自动化软件和稳定的硬件平台,Polytec 的 TopMap 光学轮廓仪能够提供面扫描表面形貌图像。

TopMap Micro.View® 非常适用于精密制造的光学光滑表面的测量与表征。

TopMap Micro.View® 的所有参数均符合 ISO 4288 和 ISO 25178 标准,Polytec 产品数据表(及公平数据表)中使用的定义遵循新版 ISO 25178-600 标准。该仪器还符合 ISO 25178-700(面扫描测量仪器校准)标准,其技术说明与我们的规格参数一致。此外,该仪器可满足 ISO 10110 中对光学元件的要求,包括采用正确滤波参数进行表面纹理测量,以及记录并显示表面缺陷、划痕、麻点和崩边等数据。

总结

新型 TopMap Micro.View® 非常适合光学抛光应用场景。这款采用先进相干扫描干涉测量技术的仪器,也将成为生产过程中极具价值的工艺优化工具。所有测量均为非接触式,且可实现完全自动化,有助于减少搬运误差。

该测量工具具备以下优势:

- 精准的定量表面表征

- 无损检测 —— 无需接触样品或进行样品制备

- 快速便捷,且可选择完全自动化操作

- 适用范围广,可用于从超精加工件到粗糙表面的各类光学材料

- 高分辨率、高重复性和高稳定性的测量结果