Visualizing haptics by non-contact vibration analysis

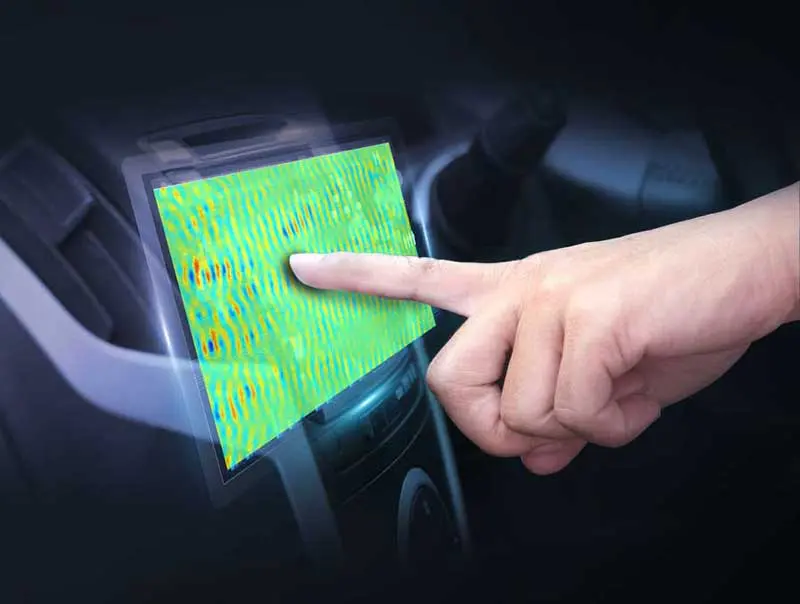

The smartphone has shown that buttons can be replaced without sacrificing comfort. The freely configurable display with gesture control has made it even easier to switch between applications. Hap2U drives this revolution in human machine interfacing forward. Its novel technology adds high fidelity haptic feedback to touch interfaces that overcome current limitations enhancing the user experience in consumer electronics. Haptic feedback touchscreens improve in vehicle safety by providing touch controls keeping the driver’s eyes on the road. Polytec laser vibrometers are the key technology for developing high-end haptic technologies.

In the following interview, Matthieu Rupin, Acoustics Director at the French innovation driver for haptic feedback Hap2U, presents his view of the future of driver and vehicle interaction. He makes it clear that, with the right technology, vibrations can be used to create virtual textures that even adapt to the speed of a finger that glides over them. And that works completely silently and not only on displays.

The core of this technology are ultrasonic wave fields that specifically and locally influence the coefficient of friction between the finger and the surface. People feel familiar surfaces and find their way around immediately. The mapping of the propagation parameters in the material is indispensable for dimensioning the ultrasonic transducers and calibrating the models.

For this purpose, Hap2U successfully uses the 3D scanning vibrometer from Polytec. Applications range from basic development, industrialization of the product to fatigue and service life tests.

In what areas can your haptic technology be used?

Haptic feedback means creating a mechanical stimulus under the user’s fingertip when interacting with a touch-sensitive interface, which is useful anywhere there is an interaction with a machine. Since the arrival of smartphones, screens have gradually replaced most interfaces that used mechanical buttons. This phenomenon can be explained by various factors ranging from the simplified differentiation of interfaces through basic programming, to the development of more robust designs by eliminating mechanical and mobile parts like knobs, sliding buttons, etc.

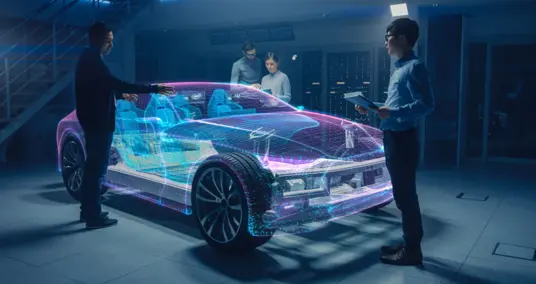

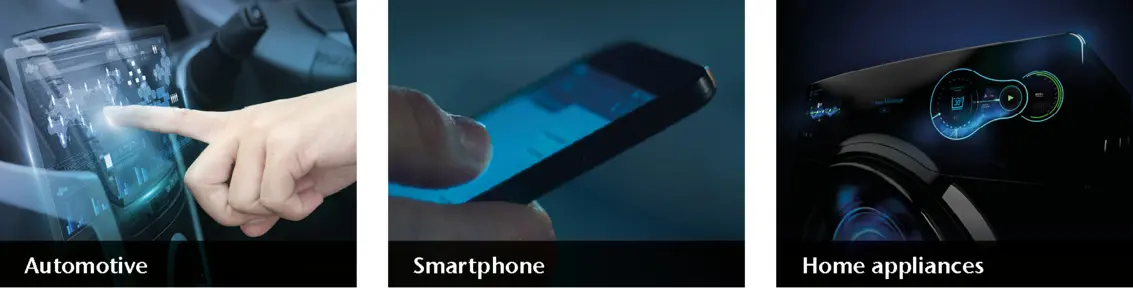

However, this widespread trend resulted in the disappearance of tactile feedback from all these interfaces where previously mechanical buttons usually provided sensory feedback due to their tangible nature. The creation of programmable tactile feedback is therefore very practical for different uses. In the automotive industry, driver screen interfaces are becoming increasingly bigger both for design and innovation purposes. This trend however, raises the issue of safety; drivers must remain fully concentrated on the road without being distracted by a visual interface. Haptic screens solve this problem by creating tactile communication between the vehicle and the user.

Thus, interaction means drivers do not have to take their eyes off the road. For home products, such as home appliances, haptic feedback technology offers ergonomics on a par with mechanical buttons. Concerning smartphones, this implies a new level of immersion in terms of all the functions that will emerge. Imagine being able to add textures to our different interactions on a website, in a game, on social media. It will even be possible to set up button controls with the screen off.

How is this different from existing technologies or from your competitors?

Hap2U technology represents the future of haptic feedback. We are all very familiar with the vibrations of a cell phone. This type of tactile feedback, which sends the user information without them having to interact with the interface, called passive touch, has two fundamental limitations; it comes with a noise and is a comprehensive event, in the sense that the whole interface vibrates.

Hap2U technology allows this proposition to go further so that it is placed directly under the user’s fingertips, thereby producing a greater degree of sophistication in the haptic feedback. In particular, it is also possible to create artificial textures which will depend on the position and speed of a finger.

All types of buttons or sliders can thus become touch sensitive again in a completely digital environment. This technology allows us to combine the flexibility of digital interfaces with a new level of tactile sensitivity, making the man machine interaction both more intuitive and more accurate.

The silent nature of the technology is also a major advantage, because as well as focusing on the tactile perception, it greatly enriches the user experience; ensuring the confidentiality of information transmitted in touch form.

Finally, this is about much more than screens. Hap2U technology also works on tactile surfaces made from plastic, wood, glass and even metal. And we have recently developed three-dimensional objects that you can locate and hold in your hand with a programmable haptic feedback feature.

These are intended to replace the moving mechanical parts of tangible buttons exposed to premature wear and tear.

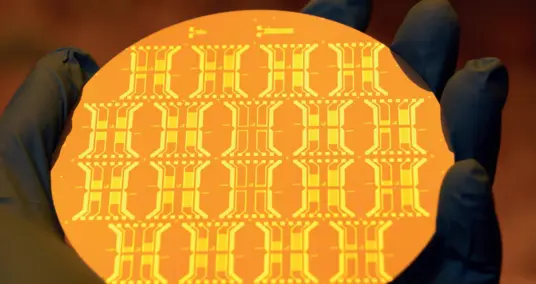

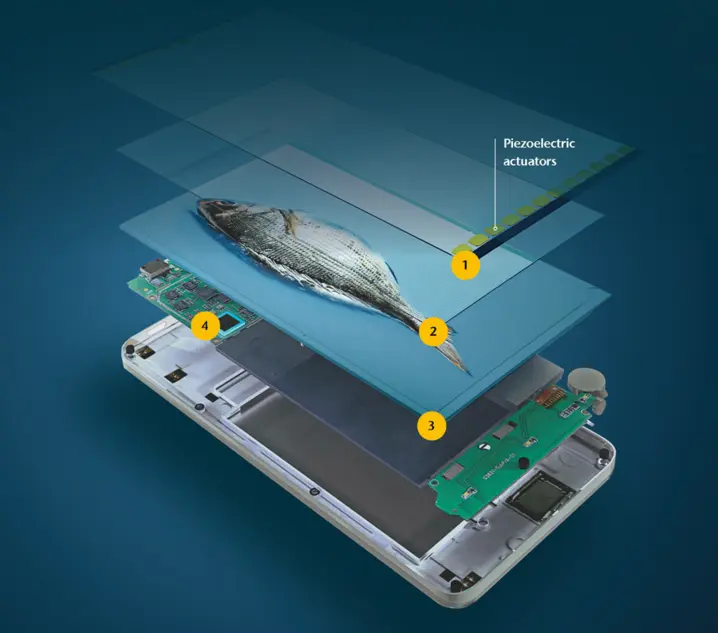

1: Cover glass with piezoelectric actuators. This 1 mm thick slab begins to vibrate under excitation of piezoelectric transducers. The amplitude of these vibrations does not exceed 2 μm.

2: Touch glass. It locates the position of the finger on the screen. Speed and direction of the finger are calculated from the measurement of its successive positions.

3: Display (LCD or OLED). As on a traditional phone or tablet, the display of the screen is modified in real-time according to the behavior of the finger on the touch interface.

4: hDriverTM. This electronic board controls piezoelectric actuators and therefore the vibrations they generate as a function of the movement of the finger on the glass slab.

What is the general working principle of your haptic displays? How is the sensation of touch actually generated?

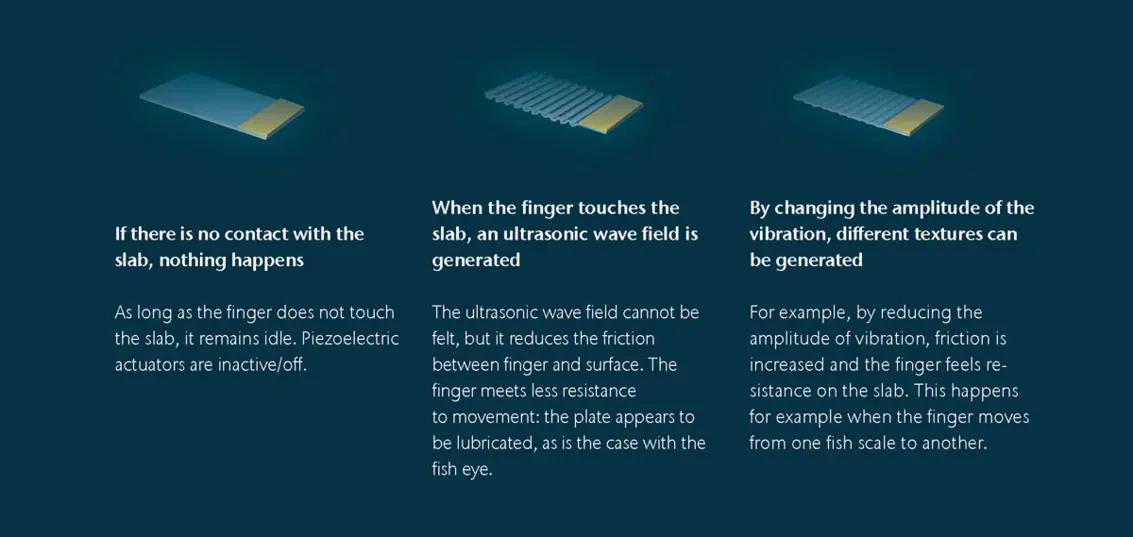

Hap2U technology generates an ultrasonic wave field on the surface that comes into contact with the skin. Using piezoelectric transducers, ultrasonic waves are emitted, vibrating several thousand times per second and they pressurize the small volume of air trapped between the fingertips and the screen. This creates an acoustic levitation force that reacts against the pressure applied by the fingertips. The contact surface area is reduced, thereby reducing the friction coefficient.

The ultrasonic vibration is thus a means to influence the friction coefficient. By controlling this vibration in real time, it is possible to emulate the friction variations similar to those encountered when exploring the real surface. In this device, piezoelectric transducers play a key role in that they have the advantage of being very reactive, they function both as an actuator and a sensor as well as being inexpensive.The challenge for our engineers is to correctly design these elements so that they provide perfect control of the vibration, regardless of the conditions of use.

What designs are demanded by the market and where does non-contact vibration testing come into play?

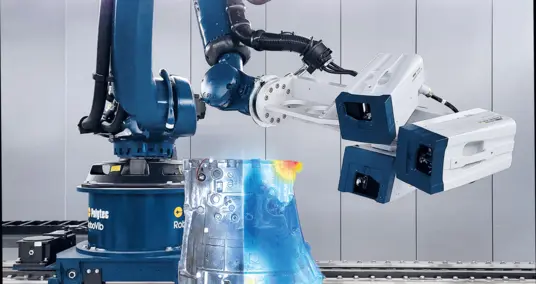

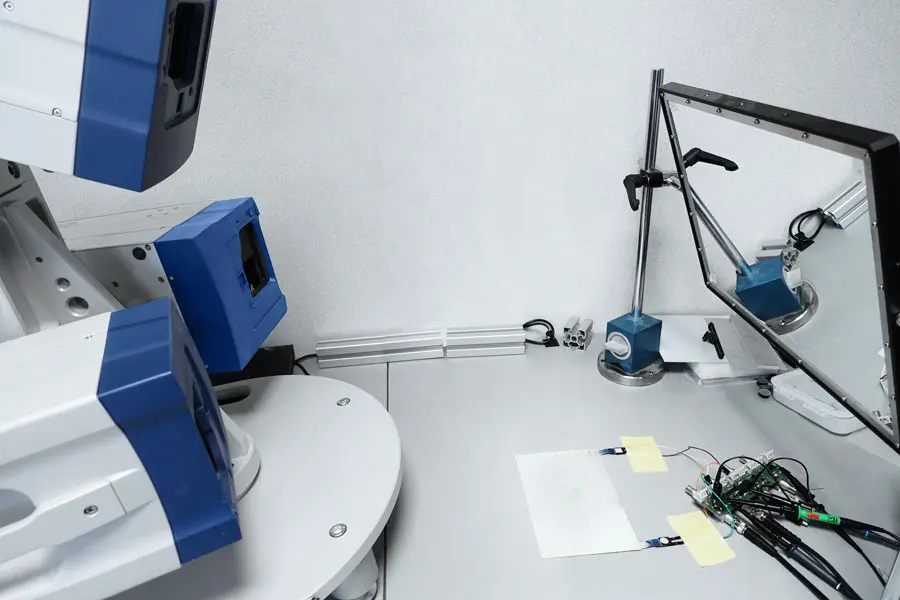

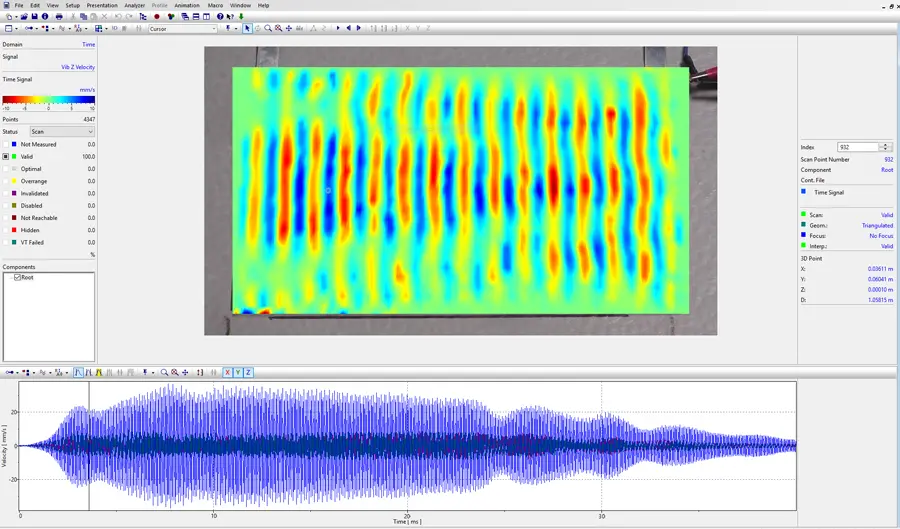

A crucial step prior to the technology going into production is to ensure that the client’s product is compatible with our limitations. We prepare a prototype for the client based on an existing product or upcoming product into which we integrate our “haptic layer”. The focus of this stage is the characterization of the client’s sample from which we extract the propagation parameters over a wide frequency range. The 3D vibration mapping with the PSV Polytec Scanning Vibrometer is done in a very short time and is the basis of our design process for the final haptic interface. Following the digital design steps, the 3D vibration characterization thus obtained allow us to control and refine our simulations if necessary.

After proof of concept, the industrialization stage follows. The focus of this phase is making our technology compliant with specific market constraints. Here again, 3D scanning vibration measurements are used to support the development of the device before and after fatigue or endurance tests. The speed of the measurements make it possible to characterize a significant number of samples in a row.

Finally, we are doing a lot of R&D in order to secure our technological lead.

In this context, the 3D scanning vibrometer is an indispensable tool to create the connection between haptic perception and surface vibrations.

In this regard, access to the in plane vibration components is invaluable. Indeed, the skin tissues that we are trying to vibrate do react in very different ways to different types of waves. The 3D scanning vibrometer is therefore the ideal tool to maximize the haptic effect from the weakest possible vibration. Complex measurements can also be finetuned to characterize the vibrating response of a user’s finger to a specific ultrasonic stimulus.

What do high-resolution, non-contact vibration measurement results tell you?

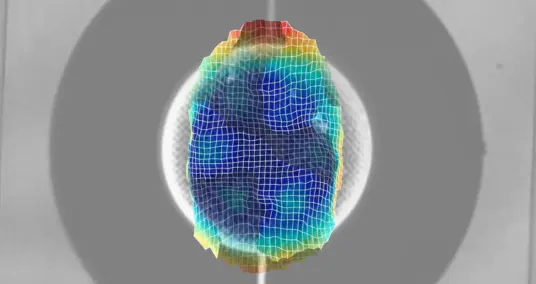

When a haptic display is being characterized, we measure the response of a large number of points crisscrossing the potentially curved surface to a pulse excitation by a source specially designed for this measurement. This way we get a wealth of spacetime information which, using advanced post processing algorithms, allow us to extract key propagation parameters. This information primarily allows us to precisely design our actuators to optimize the effectiveness of our device. But the measurements also open up new perspectives.

With the 3D vibration data we can study the x, y and z components of the ultrasonic wave field separately, allowing us to develop new haptic functions. Also, the 3D scanning vibrometer has proven to be crucial for a range of inventions we have new patents registered for, which are currently being validated.

Where do you see 3D scanning vibration measurement compared to what you were doing before?

When we started out we were well aware of the importance of the non-contact nature of the laser Doppler vibrometry measurements, so we bought a 1D fiber optic laser vibrometer. This allowed us to link the out of plane vibration amplitude to the driving parameters of the actuators. Then, we paired the laser vibrometer with stepper motors controlling the position on the XY plane which allowed us to map the out of plane vibration field and therefore finely characterize the propagation of waves on the various surfaces.

Importantly for us the 3D scanning vibrometer has considerably reduced the amount of time needed to characterize a sample. It also enables us to measure curved surfaces which are increasingly important in our applications. Also, we have since been able to increase our use of the information rich laser measurements which will allow us to significantly accelerate our growth.

Thank you very much for this interview, Matthieu.