Powder coating quality depends on coating thickness and uniformity, especially at critical points, making measurement essential for quality control. Photothermal measurement systems offer practical solutions, suitable for nearly all opaque or semi-transparent coatings on common substrates. With measurement times of about one second, they can be integrated directly into production—even enabling 100% quality control in applications where this was previously impossible. New photothermal systems come pre-calibrated, simplifying their use.

Powder coatings provide many benefits: chemically and mechanically durable surfaces, good coverage of minor substrate irregularities, no harmful solvents or wastewater, and easy automation without the need for explosion-proof painting rooms. No primer is necessary, and powder coatings offer high UV protection even without clear coats. Typical layer thickness ranges from 60 to 120 μm but varies depending on application and surface texture.

Commonly used on individual parts as well as small and large series in industry and crafts, typical substrates include steel, galvanized steel, and aluminum. Main applications include household appliances and façade elements like windows and doors.

Reduce waste and energy costs

Controlling coating thickness during quality checks is crucial to ensure protection and aesthetics. Inline measurement during production—rather than at the end—allows early error correction before curing in the oven, preventing waste altogether.

They also save heating energy since only defect-free coated products enter the oven. This optimizes the coating process, as it’s common to apply layers 10 to 30% thicker than necessary to be safe. Thickness control thus significantly reduces material use. Thinner layers cure faster in the oven, saving even more energy.

Inline thickness measurement systems often pay off within months due to powder savings alone. For example, an aluminum profile manufacturer for window frames reduced powder consumption by 10%, nearly 30 tons per year, saving around €150,000 annually (Image 1).

Photothermal Measurement Method

Polytec now offers a contactless system based on photothermal measurement, specially designed for powder coating thickness (Image 2). Using lasers and infrared sensors, the coating is measured with a repeatability of ±1 µm or ±3% of the measured value. Measurable thickness ranges from 0.2 to 500 µm.

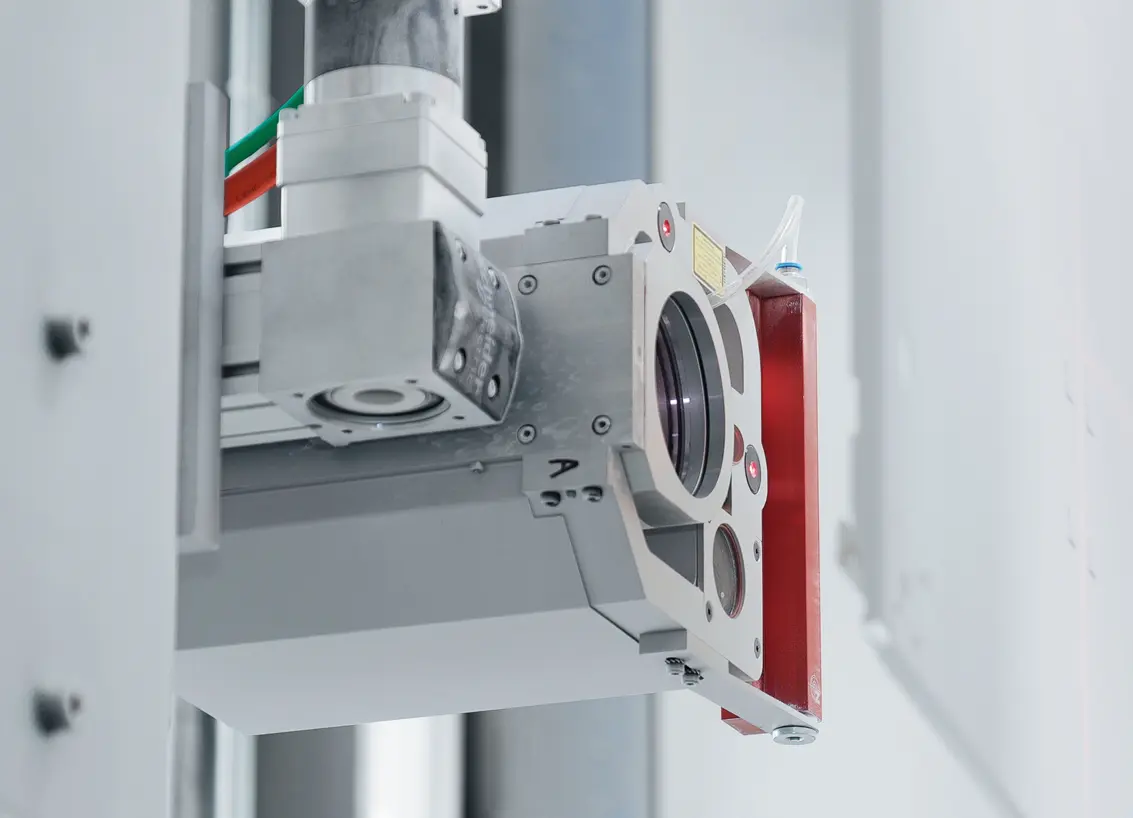

The measuring head (Image 3) is equipped with a camera for object recognition, a laser for targeting automatically generated measurement points, and a blow-off unit. Multiple measuring heads can be combined, for example, to measure coating thickness from different sides.

Before measurement, the object’s shape is detected. The so-called Detection Gate, consisting of a light curtain, recognizes features like cutouts, which are then considered when generating measurement points. The measuring head, which moves along two axes, measures only at locations that are actually coated. Its working distance ranges between 150 and 250 mm.

The basic principle is simple: The laser-based photothermal measurement relies on heating a sample surface by laser irradiation. This heating diffuses depending on the material and coating thickness. The sample is irradiated by the laser at defined points, and the coating thickness is calculated from the thermal response at these points using specific algorithms. This works reliably even under industrial conditions. Since the excitation laser only causes a slight temperature increase of a few degrees Celsius, neither the object nor the coating is affected or damaged during the measurement.

The process is very fast: each measurement takes less than one second. The inline system is designed for epoxy and polyester coatings on metallic, polymer, and composite substrates, as well as for enamel coatings. It can measure both immediately after coating application and after curing or drying, accommodating different conveyor speeds and changing objects.

Pre-calibrated and easy to integrate

Additionally, the measurement is based on a physical model that allows pre-calibration of the system according to the application’s environmental conditions. Measurement time, distance, accuracy, and laser intensity can thus be tuned at the factory to fit the specific application.

On-site calibration is quick and simple. Thanks to this technology, a complete recalibration is not required with product changes. Necessary parameters are stored in the measurement system, already optimized for the application. A reference standard ensures stable results.

With dimensions of 120 mm length, 66 mm width, and 66 mm height, the measuring head is very compact and can be easily integrated into the production line. User-friendly interfaces are available for automation. Measurement data can be automatically saved and archived. On the clear control terminal (Image 4), all measurement results are displayed clearly in real time and can be analyzed in more detail if needed.