In many industrial products, coating quality plays a crucial role—for example, the material thickness, color, gloss, or adhesion of one or more layers on a substrate. Applications range from non-stick coatings on cookware to metallic cylinder coatings in the automotive industry and composite materials in aerospace engineering. New photothermal measurement systems are suitable for almost all opaque or semi-transparent coatings on common substrates. Measurement times of under one second allow direct integration into the production process—even in applications where 100% quality control was previously impossible.

There are various methods to measure coating or paint thickness. The trend today is toward non-contact methods, as they are non-destructive and do not damage sensitive surfaces. However, the nature of the products often limits the choice of testing methods: optical methods are generally suitable only for transparent coatings, while inductive or ultrasonic systems are inherently too slow to integrate into production processes with short cycle times, making them unsuitable for inline measurements and 100% inspection.

A promising alternative is a method from the French manufacturer Enovasense for measuring the thickness of opaque and semi-transparent coatings. It works for almost all coatings on common substrates such as paints, galvanizations, and metallizations on plastic, metal, wood, or glass, making it nearly universally applicable.

Instant measurement in industrial processes

The laser-based coating thickness measurement system works completely contact-free. Using lasers and infrared sensors, it measures opaque, semi-transparent, or nearly transparent coatings from working distances of 40 to 200 mm. Typical repeatability is ±1 µm or ±3 % of the measured value. The laser-based photothermal radiometry relies on heating the sample surface with laser irradiation. This heat spreads as a diffusion process depending on the material and coating thickness.

The test object is irradiated at defined points by the laser. From the thermal signature at these measurement points, the coating thickness can be calculated using appropriate algorithms. This works reliably even under industrial conditions, such as fast-moving conveyor belts, high temperatures, or wet and brittle surfaces. Since the excitation laser only causes a slight temperature rise of a few degrees Celsius, neither the object nor the coating is affected or damaged during measurement.

The method is extremely fast. The measurement itself takes less than one second. Coating thickness measurements at conveyor speeds of 40 m/min have already been successfully achieved. This high process suitability allows 100 % quality control in many areas where it was previously impossible.

In addition, the measurement is based on a physical model, which allows the system to be pre-calibrated according to the environmental conditions of the application. This means that measurement time, distance, accuracy, and laser intensity can be coordinated from the factory to suit the application. On-site calibration is then faster and easier than with conventional methods, and for some applications, it can even be completely omitted.

Compact, lightweight sensor head

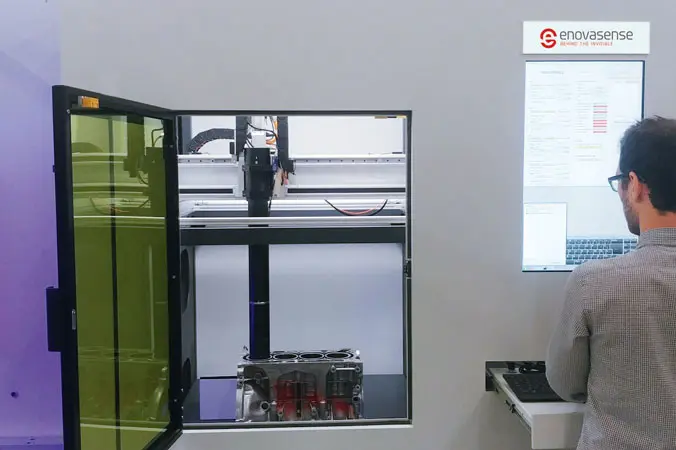

The complete measurement system essentially consists of two units (see image above): the main device with laser and evaluation electronics, and the lightweight, compact sensor head. The small dimensions of the sensor head (75 × 32 × 41 mm) and its weight of 150 g allow measurements in previously hard-to-reach locations. Mounting on a robotic arm is easily possible. The sensor head is connected to the main device via a cable containing both electrical lines and an optical fiber.

The connection cable can be up to 20 m long, providing greater installation flexibility. Multiple heads can also be connected to the measurement unit via switches, for instance, to check coating thickness sequentially at different sections of a production line. Measurement time per point typically ranges from 0.3 to 2 s, depending on the coating–substrate combination; spatial resolution depends on the laser spot size. Depending on the application, spot diameters of 0.3, 0.6, 11, or 20 mm are possible.

Many applications

Due to its speed, accuracy, and flexibility, the coating thickness measurement system is almost universally applicable, and the areas of application are broad. In the automotive or aerospace industry, for example, it is suitable for measuring paint thickness on metal or plastic. Likewise, chrome and metal coatings on plastics can be inspected, as well as chassis galvanization or metal coatings in engines, e.g., in cylinder bores. Together with a French automobile manufacturer, a patented automation solution was developed for this purpose (Figure 1).

Interesting applications can also be found in completely different industries, such as in consumer goods. The range here extends from measuring the thickness of stained glass to layer thickness determinations on housing parts or cookware, up to checking screen printing on glass-ceramic plates. Even during coating, the thickness can be checked at any time to ensure that the correct amount is applied. Under certain conditions, even multiple layers can be monitored