The automation of production control and the associated measurement processes and evaluations are a central topic in modern manufacturing technology. They relieve the burden of routine work and make production control more efficient. However, this requires that the Laser Doppler vibrometers used for quality control can be individually integrated into the production environment. Cycle times and flexibility are important factors here. Laser vibrometers therefore provide intuitive and powerful interfaces for the automation of measurement data acquisition and analysis. Measurement ranges, focus and status values, for example, can then be exchanged between the testing software and the sensor according to your own requirements.

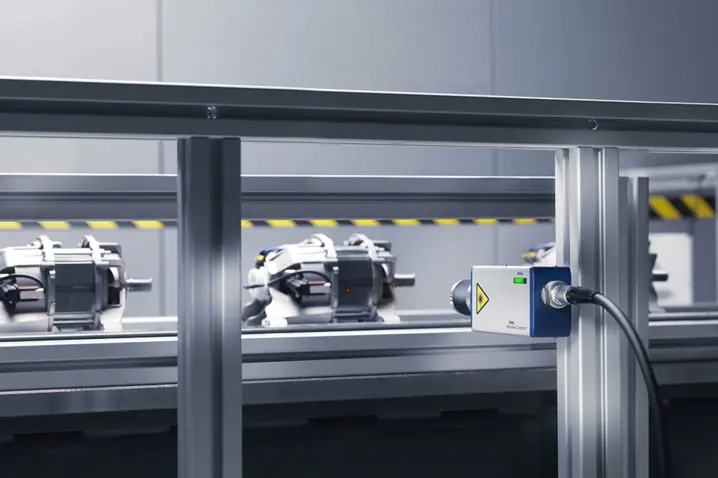

Laser Doppler vibrometers have proven themselves both in industry and in research when developers and scientists measure and optimize the dynamics and acoustics of a wide variety of objects. Due to the fact that they measure optically and therefore at a distance and without influencing the object being measured, 100% quality control in production lines also benefits from this technology. With real-time measurement data, high repeatability and low operating costs, they fit into any automation environment (Fig. 1).

Until now, such integration was by no means trivial and required some programming effort, for example, if only the measurement data were to be transferred live into the in-house test program without detours via data files. Polytec has addressed this problem and provides powerful interfaces and drivers for its laser Doppler vibrometers in end-of-line inspection as well as options for automating measurement data acquisition and analysis that cover a wide range of application requirements. This allows users to optimally integrate the laser sensors into their own automation environment according to their needs.

Integrate directly into external programs

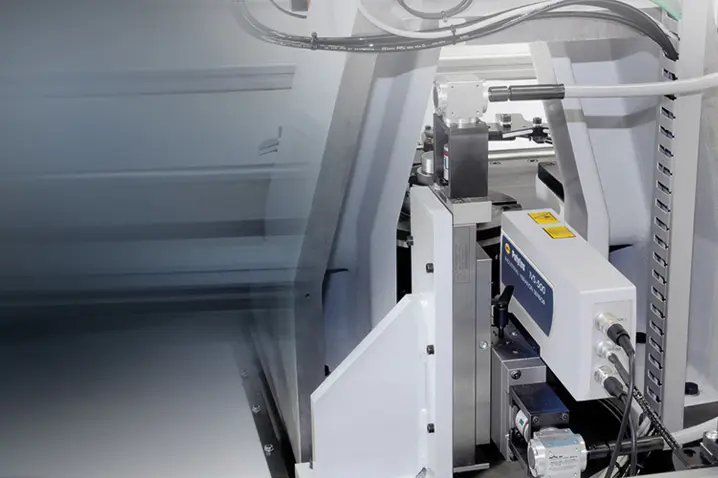

With ‘Polytec Device Communication’, for example, an open-source and therefore cross-platform driver is available for the laser sensors under Microsoft Windows and Linux, which can be used to easily program data access and hardware control as well as read out the operating states. The TCP/IP interface ensures robust communication and the streaming of digital vibration data up to the MHz range. The rolling bearing manufacturer SKF, for example, has used this driver to seamlessly integrate an industrial laser vibrometer into its self-programmed testing software as part of its zero-defect strategy for 100% quality control (Fig. 2). The measurement parameters can now be set via the Ethernet interface using the software and the vibration measurement data can be transmitted completely digitally. In addition to pass/fail testing, the measurement data even enables a differentiated fault diagnosis for rejected parts.

Controlling the system software with external programs

Alternatively, users can also access the laser vibrometers via a COM/DCOM interface. This is ideal for users who work with established programming tools such as MATLAB or the Python programming language, for example. They can use the interface to access all functions of the system software for controlling the measurement system and thus integrate the device control into their own automation application. Well-documented objects and methods can be easily integrated into the application-specific codes.

For full access to the measurement data - including all properties such as geometry and measurement parameters - there is also the freely available ‘API Polytec File Access’ (Application Programming Interface), i.e. a collection of commands, functions and objects that programmers can use to interact with the measurement system. Extensive object references and sample programs for Python, C++, MATLAB®, .NET and Microsoft Excel make it easy to get started quickly.

The integration of the vibrometers also makes it possible to realize automation solutions that require other measured variables in addition to vibration data. Researchers at KAIST (Korea Advanced Institute of Science and Technology), for example, combine a PSV scanning vibrometer with a scanning distance meter to expand the database for condition monitoring on bridges (Fig. 3).

To do this, the scanning measurement beams of both measurement systems must be precisely synchronized. The COM/DCOM automation interface of the PSV is used here to move to defined measuring points from an industrial PC as a central server, to focus the laser beam and to start the measurements. The collected measurement data from both measurement systems is merged into a central data set by the server during the measurement. The COM/DCOM Automation Interface enables simple and effective access to all system functions of the vibrometer.

Integrated macro language

With the integrated macro language of the Polytec system software, vibrometer measurements and evaluations can be automated directly in the Polytec system environment. The easy-to-use macro language Basic® provides access to all important functions in an object-oriented programming environment. The macros set measurement settings, start measurements, apply mathematical operators to the measurement data, write them to files or to a separate channel (“user-defined data set”) of the measurement file. This also makes batch processing of measurement data possible. This significantly increases the productivity of a laser Doppler vibrometer, as an application in the quality assurance of sonotrodes for ultrasonic welding shows.

Here, consistent energy distribution along the active surface is crucial for medical and food safety. To ensure the best welding results, the amplitude values at predefined points are measured using a PSV scanning vibrometer. The maximum peak values for each point are stored in a database together with quality indicators for each tested sonotrode serial number. A macro tailored to the quality assurance task with a specific user interface guides the operator through the testing and documentation process, making quality control more efficient.

The examples show that thanks to their software and the interfaces and drivers provided, Laser Doppler vibrometers can be integrated into a wide range of automation applications to suit individual requirements. For more information, visit the Polytec expert platform (https://www.polytec.com/de/ivs-experte). Here, users will find practical tips and tricks for installing and operating laser Doppler vibrometers. Vibrometer experts are also available to provide personal advice and support.