In wind turbines, fiber optic sensors are used not only for monitoring but also for control, e.g., for blade pitch adjustment based on load measurements of the blades.

Fiber Bragg Gratings (hereinafter referred to as FBGs) are a good choice in many applications for measuring mechanical quantities or temperatures. Especially under special environmental conditions or with a large number of sensors, FBGs show their advantages.

Advantages of fiber optic sensors

The FBG technology is fundamentally a purely optical measurement method, in which the light never leaves the glass fiber. This results in special advantages such as electromagnetic immunity, good chemical resistance, small dimensions and weights, long ranges, and multiplexing capabilities—properties that electrical sensors do not have or only have to a limited extent. FBGs are therefore not a replacement for their electrical counterparts but often the only solution for special measurement tasks.

Practical work with FBGs

However, working with "bare," i.e., not pre-assembled FBGs for the intended application purpose, is often not practical for the end user. Some of the most important application-specific adaptations concern the fixation of the sensor on the measurement object, the mechanical protection of the glass fiber in the sensor area and in the lead lines, the compensation of cross-sensitivities (for example, to distinguish between strain and temperature), as well as solutions for detecting quantities that cannot be measured directly.

Polytec offers a wide selection of ready-to-use FBG sensors that can measure various parameters such as temperature, strain, acceleration, and inclination. The sensors can be operated individually or in series (measurement chain), and different sensor types can also be combined. Each sensor is uniquely identifiable by its own wavelength, so that several sensors with different measured variables can be used simultaneously on one measurement channel. This makes it easy to set up complete sensor networks.

Strain Sensors

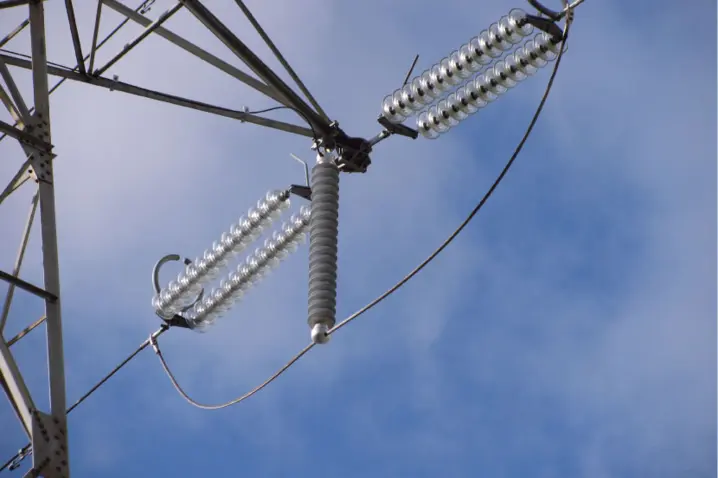

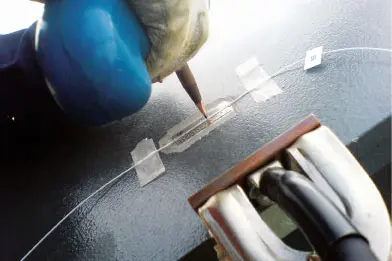

For strain measurements in the laboratory, a polyimide-based patch is available, which in terms of handling corresponds to a classic electrical strain gauge (SG). This means that after surface treatment of the test object, the patch is glued onto the measurement point and thus transmits the strains of the test object to the embedded FBG sensor. For harsh environmental conditions, especially outdoors, a carbon fiber-reinforced variant is also available. Images 2 to 5 show some interesting outdoor applications.

For applications where gluing is not possible, screw-on sensors are available, which work integrally due to their extended length (10 or 100 cm). For permanent use, for example in concrete components, there are also castable versions (image 5), which can be integrated directly into the component during manufacturing.

To suppress the inherent cross-sensitivity between temperature and strain in FBGs, the temperature can be measured with a separate temperature sensor near the measurement location, so that the unintended temperature effect can be compensated. An elegant alternative is the use of athermal FBGs, in which the temperature effect is compensated by the internal design of the overall sensor. For the user, this sensor behaves as a pure strain sensor. The measurement range of the strain sensors is between 0 and 4000 µm/m with a resolution of 1 µm/m.

Temperature measurement

Through a suitable housing design, an FBG can also be configured as a pure temperature sensor, for example by stress-free mounting inside a compact housing. To keep the thermal and mechanical coupling to the measurement object as simple as possible, a variety of different housing designs have been developed. In addition to the universal housing, a weldable or castable housing can be used. The temperature range extends from –20 °C to +80 °C for standard sensors and up to +150 °C for high-temperature sensors.

Acceleration and inclination measurement

If mechanical quantities other than those previously considered are to be measured with an FBG, the measured quantity must be converted into strain or compression of the fiber. This is done by a mechanical transducer, so that the measured quantity can be derived from the wavelength change of the Bragg grating using a corresponding calibration factor. For example, Polytec offers single-axis accelerometers that measure accelerations up to ±40 G. By linking three sensors, measurements can also be taken in all three spatial directions.

Furthermore, inclination sensors are available that can detect inclinations up to 10 degrees with an accuracy of 0.01 degrees. This high sensitivity also makes the sensor interesting for safety applications.