The growing electric and hybrid vehicles market faces new demands on product acoustic quality. The acoustical emission behavior of electric drivetrains is clearly different from that of conventional drives. The IPEK – Institute for Product Engineering at the Karlsruhe Institute of Technology (KIT) examined these phenomena.

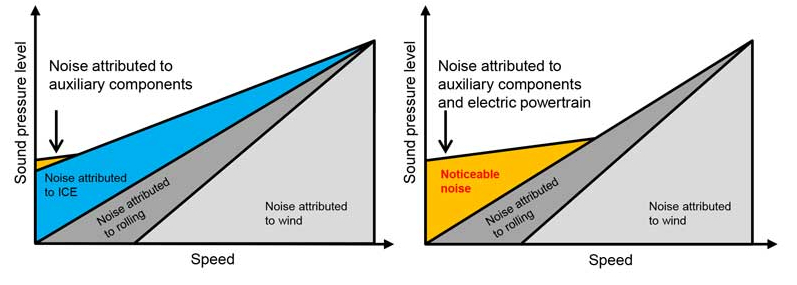

Drive comfort is a significant decision-making criterion when purchasing a vehicle. The acoustic quality plays a prime role especially for vehicles with electric drivetrains, because the sound is not masked by a running combustion engine (figure 1).

One challenge with the interior noise of a vehicle is that methods and experiences are lacking with regard to the excitation of noise and its transmission mechanisms. Another is that with electric and hybrid drive systems, depending on the topology of the specific electric motor and the drivetrain, higher orders and therefore tonal components of the interior noise become apparent and need to be addressed during the development.

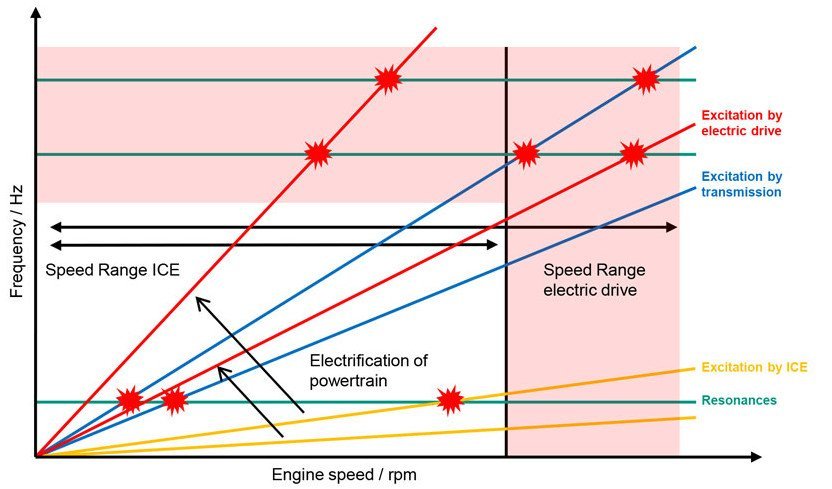

Another difference is the much higher rpm range of electric motors as compared to combustion engines. As a consequence, the excitations caused by an electric motor are in general at higher orders, resulting in higher excited frequencies (figure 2).

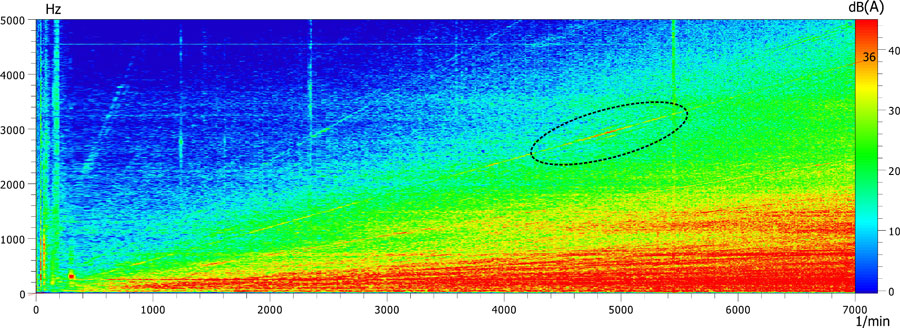

Due to these conflicts, the electric drive requires a re-evaluation and examination for each vehicle. (figure 3).

In order to evaluate the acoustic quality of the interior noise of electric vehicles, it is critical to analyze the acoustic power emitted by the drivetrain in the frequency range from 20 Hz to approximately 16 kHz. It’s then possible to estimate the noise contribution of the drivetrain – in combination with the structure-borne noise transferred into the car body – to interior vehicle noise.

In terms of the machine- acoustic base equation, the emitted acoustic power is directly correlated with the square of the velocity normal to the radiating surface. Therefore – under the simplifying assumption of a constant radiation factor – the acoustic radiation of a drivetrain or the individual components can be approximated and validated by the measured surface velocity. The definition of limit values on the basis of the surface velocities offers several advantages.

Surface velocities can be measured reliably and reproducibly on test benches that do not need to be anechoic. Secondly, this procedure allows the contribution of the individual subsurfaces to the total noise to be calculated, enabling an analysis of the excitation and sound path on the structural level.

3D Scanning Vibrometers are used to capture surface velocities without contact with high local resolution made possible by the Laser Doppler Principle. This is particularly advantageous for electric drive systems because higher frequencies are excited than in conventional drive systems.

As part of a research project, the IPEK – Institute for Product Engineering at the Karlsruhe Institute of Technology (KIT) carried out acoustic measurements in an anechoic drivetrain test cell. The acoustic characteristics of the electric drive train were examined.

In addition to acquiring and analyzing the electrical, mechanical and acoustic quantities, the surface velocities were examined on the drivetrain at critical operating points with a 3D Scanning Vibrometer. Attention was focused primarily on the electric motor and the gear mechanism.

Measurements showed elevations of the surface velocities analogous to the elevations of the acoustic pressure in the far field. During the examinations the researchers discovered by means of locally high-resolution surface velocities that the excitation of the structure deriving from the electric motor is emitted mainly by the coupled gear.

Prof. Dr.-Ing. Albert Albers, Head of the IPEK summarizes:

The validation of technical systems at each phase of the development process is a central issue in the product development. For this purpose, the IPEK is developing the X-in-the-Loop Framework (XiL), a method for the universal and process-related validation of technical systems with focus on the vehicle respectively drive system development.

As part of a more in-depth analysis, the excitation and transmission mechanism of the structural vibrations could be further limited enabling further targeted examinations at the component level.

IPEK’s study proves that there is a strong correlation between the distribution of surface velocities and the acoustic pressure measured in the far field. The higher excitation frequencies of the electric drive with coupled gears are captured without any problems by the optical sensors that are characterized by high spatial resolution and a non-contact measuring principle.

The vibration measurement technology allowed IPEK to acquire the acoustic properties of the product without requiring any specific acoustic properties of the measuring room.

Images courtesy: Images courtesy of the authors unless otherwise specified. Cover image: ©istock.com/franckreporter