Hygiene is crucial across all areas of the food industry. This is especially true for dairy products like yogurt, which are highly vulnerable to contamination by microorganisms and mold spores. These can come from various sources, including the packaging materials used. Therefore, disinfecting yogurt cups and sealing foils before filling and sealing is a critical step in a safe production process. Pulsed UV light offers a practical, eco-friendly solution for this. It quickly and residue-free deactivates a wide range of microorganisms and spores. The systems are also easy to integrate into existing production lines.

Traditionally, yogurt manufacturers rely on chemical cleaning for packaging disinfection, most commonly using hydrogen peroxide—a method that has proven effective in practice. However, this approach comes with drawbacks. The use of chemicals always involves some environmental impact, and waste generation is unavoidable.

Likewise, steam disinfection can damage heat-sensitive packaging materials, presenting additional challenges. Therefore, alternatives with a better environmental footprint are beneficial for both equipment manufacturers and dairy producers to remain competitive in the future.

Cleanliness up to Log 6 disinfection level

A well-known alternative to chemical disinfection is UV light irradiation. The effectiveness of UV disinfection depends on the dose: the intensity must be high enough and the exposure time long enough to deactivate microorganisms and viruses as required. Continuous UV exposure can damage microbial DNA, but often fails to overcome natural repair mechanisms. As a result, germ counts may rise again after packaging, potentially reducing the shelf life of dairy products.

Pulsed xenon light from Polytec uses a different approach (Figure 1): it emits short but extremely high-energy UV light pulses that kill virtually all known pathogens and also destroy the DNA repair mechanisms of microorganisms. In addition to damaging DNA, the water inside the cells evaporates, causing the cell walls to rupture.

The method is FDA-approved and, depending on the application, can meet hygiene standards up to Log 6 and beyond—eliminating up to 99.9999% of harmful bacteria, fungi, or viruses, matching the disinfection level of an operating room. Since pulsed light generates little to no heat, it is suitable for a wide range of materials, including heat-sensitive plastics.

These properties make pulsed light systems ideal for disinfecting yogurt cups before filling. They operate at high production speeds and can be easily integrated into filling machines, conveyor systems, or other points in the production process. Depending on the application, different UV lamps and housings can be combined into systems whose UV output is precisely tailored to the specific use case.

In principle, any food container with a sufficiently wide opening can be disinfected this way, including bottles and cans. The food-safe, washable lamp housings are made of stainless steel and meet IP67 and NEMA 4X standards. The lamp unit can be easily mounted to existing conveyor systems and positioned so that it does not interfere with the movement of packaging on the line.

Application Example: Linear Cup Filling System

Greek machine manufacturer Alfa Machine has integrated Polytec’s pulsed xenon systems into its Fill-Seal machines for dairy products (Figure 2)—one system for disinfecting the cups and another for the sealing foil. The linear filling line has a production capacity of 15,000 to 18,000 cups per hour, depending on the product's viscosity.

It is suitable for all liquid to viscous food products such as yogurt, dairy creams, desserts, ready meals, butter, or spreadable cheese. The pulsed UV technology delivers high peak energy for effective decontamination of cups and lids, achieving up to Log 4 disinfection—eliminating up to 99.99% of microorganisms reliably.

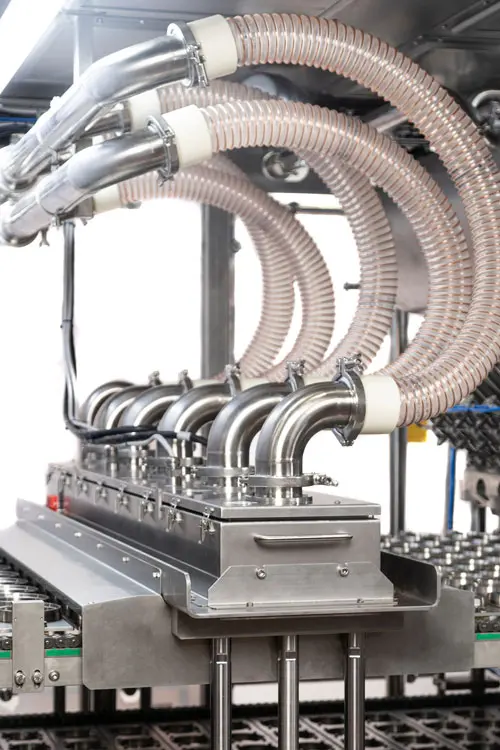

Each cup is disinfected with UV pulses. The lamp is positioned above the conveyor belt, treating 10 cups simultaneously (Figure 3). This takes only 0.5 to 1 second, easily keeping up with the high production speed.

The sealing foil for the lid is disinfected in the same way and at high speed. The second UV lamp is integrated after the foil feeder in the system (Figure 4)

The lamps operate with high efficiency, using less energy than conventional disinfection methods. Cooling ensures dairy products don’t heat up during disinfection, and the stainless steel, washable lamp housing can be easily cleaned with steam if needed. The system is user-friendly and simple to operate, reducing operational complexity. Users avoid waste disposal, chemical handling, and chemical residues altogether.