Printed electronics are conquering the industrial application market. The technology used is well established, but not all applications can be realized with these conventional methods. The key role of the sintering process is explained here.

Photonic sintering is a process in which tiny particles are fused together using a high-energy xenon light pulse. This allows electronic circuits to be produced via conventional printing techniques such as inkjet or screen printing. Special inks containing silver or copper materials enable the creation of solid, conductive tracks through photonic sintering. With pulses lasting only a few milliseconds, even heat-sensitive substrates can be used. Photonic sintering therefore promises to become a key technology for utilizing heat-sensitive substrates while achieving high throughput in printed electronics.

The wide variety of inks, substrates, and printing processes, as well as the differing requirements for the final product—such as adhesion, flexibility, and transparency—demand precise pulse control. Xenon Sinteron systems, for example, allow exact adjustment of pulse energy, pulse duration, and frequency to achieve an optimal sintering temperature.

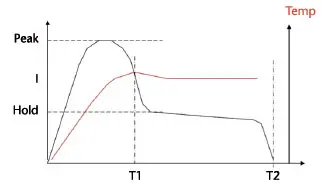

However, for thick conductive structures, it is not enough to reach the temperature at the conductor track structure using a single pulse; it must be maintained so that the heat can penetrate and the deeper layers can also be sintered. If the temperature is not maintained over a longer period of time, unsintered ink remains beneath the surface. The result is poor conductivity and insufficient adhesion to the substrate. Xenon Corporation, Polytec's partner for xenon flash systems, has developed the double pulse process for the photonic sintering of thick layers.

The new S-2300 system with dual pulse technology allows the user to determine both the peak energy that enables sintering and the definition of a hold pulse that maintains the sintering temperature over a certain period of time in order to sinter thick layers consistently. This provides the flexibility for optimally adjusted processes and is still easy to use, as only two parameters need to be set.