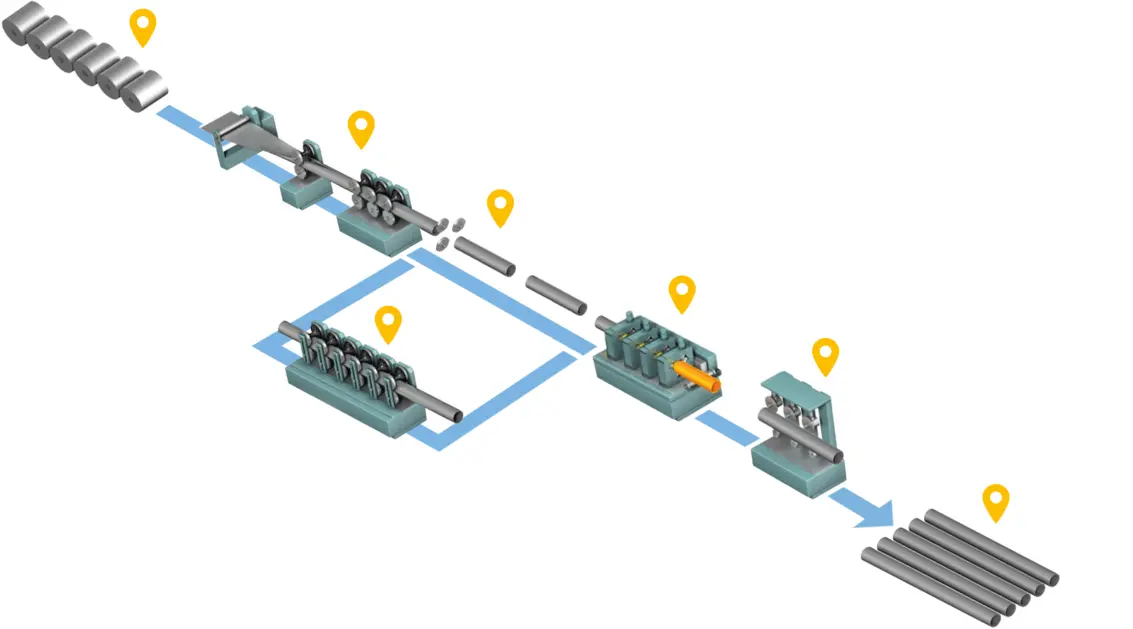

The Polytec LSV laser velocimeter offers process control with utmost precision for the production of flat, round and long products based on laser-precise and repeatable measurement of e.g. tube speed during welding of longitudinal welded pipes or heat treatment of tubes, for cut-to-length control, for position tracking in NDT systems and many more measurement and control tasks in the tube and pipe production (Fig 1).

The non-contact measuring LSV Laser Surface Velocimeters are easy to integrate into production lines. The compact and robust sensors operate reliably under harsh production conditions, unaffected by dirt or dust and on all surfaces, even on red-hot metal. Unlike conventional contact-based measurement methods (e.g. encoders), the LSV sensors are a maintenance-free "optical encoder" which do neither suffer from slippage nor wear, thus reducing scrap and avoiding maintenance stops and downtime.

Process control of seamless rolled tube production

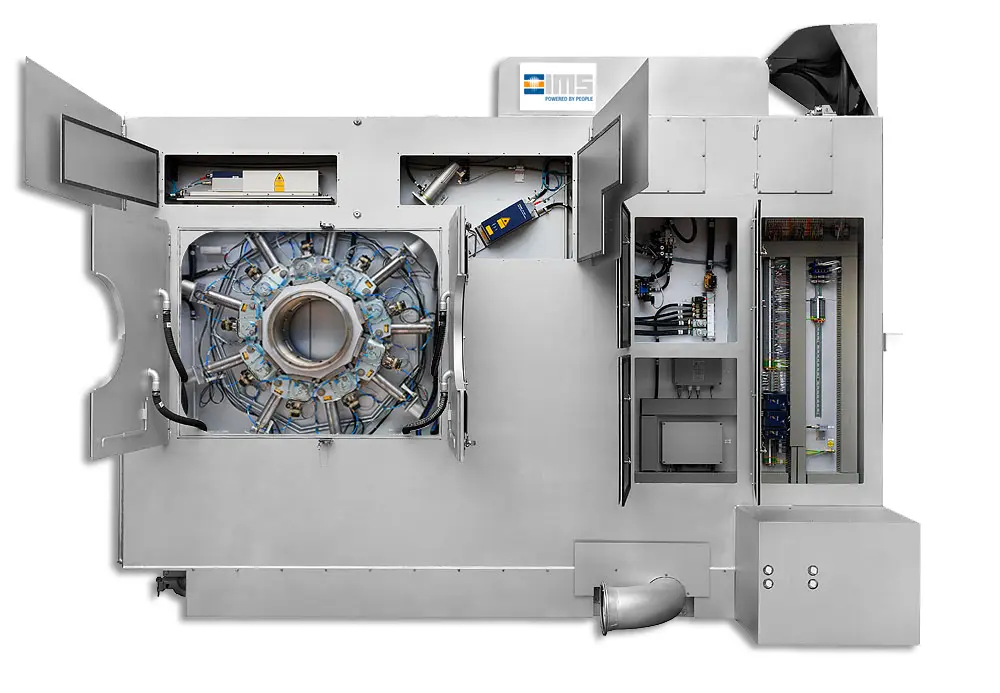

Leading manufacturers of industrial measurement and control technology, such as IMS Messsysteme GmbH, also rely on the use of optical encoders from Polytec:

"The LSV Laser Surface Velocimeter by Polytec provides process-reliable and highly accurate speed and length information - even under the most difficult environmental conditions. This makes the LSV laser sensors the perfect matching sensor technology in tube rolling mills"

IMS Messsysteme GmbH uses the Polytec LSV as combination with their radiometric pipe wall thickness measurement in the O-frame. The efficient and process-reliable production of tubes requires tight tolerances and at the same time saving raw materials and energy, which calls for precise, reliable and stable measuring equipment. Attributes that characterize the Polytec LSV, making it the sensor of choice for tube and pipe manufacturers, providing measurement values over the entire pipe length for any length and circumference position. The continuous measurement and storage of all measured values over the entire tube length primarily serves the purpose of process control, optimization of production, and in-process quality control.

Laser velocimeters use the Doppler effect, to evaluate the backscattered light from a moving object surface. Two superimposed laser beams create an interference pattern that modulates the intensity of the backscattered light. This modulation frequency is analyzed and directly proportional to the velocity. This laser Doppler sensor technology can be easily and quickly integrated into existing processes and production lines, substituting conventional tactile methods such as encoders and measuring wheels for a future-proof process control.