The success of sterile environments in the pharmaceutical, medical, and food industries depends on transferring materials in and out without causing microbial contamination. Conventional surface sterilization methods using gas or UV light are slow and labor-intensive. In contrast, pulsed UV light is easy to apply, chemical- and residue-free, unaffected by immunity or heated surfaces, and acts within milliseconds.

Pharmaceutical, medical, and increasingly food companies manufacture many of their products in cleanrooms. In these industries, cleanrooms do not only mean dust-free or low-particle air, as in semiconductor and electronics manufacturing, but also sterility. This is typically achieved through filtered airflow, consistent (over)pressure, temperature and humidity control, appropriate work clothing, and various other measures. Equally crucial is the sterility of materials introduced into the cleanroom.

Larger cleanroom facilities have airlocks where materials are sterilized using hydrogen peroxide gas, peracetic acid, or ozone-based methods. Each method requires prior cleaning of the surfaces to be sterilized. Subsequently, the gases must be vented, and chemicals or resulting hazardous waste must be disposed of.

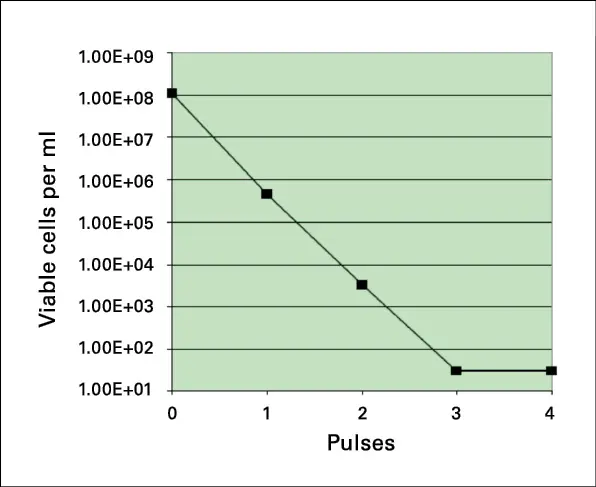

Another method is UV light irradiation, which exploits photochemical sterilization. Molecular bonds are broken, ultimately destroying DNA and cells. This occurs when the photon energy at a given wavelength equals or exceeds the strength of the biomolecular-chemical bonds. Biochemical studies have shown that wavelengths between 250 and 280 nm have the greatest effect on nucleic acids, meaning DNA exposed to these wavelengths is most severely damaged. Photochemical sterilization is thus achieved by applying extremely high UV radiation in germicidal wavelengths, irreversibly damaging molecular bonds and causing cell death.

Conventional mercury-vapor UV lamps are inherently weak light sources and cannot achieve a radiation flux high enough to overwhelm DNA repair mechanisms in a short time. Achieving a sufficient effect requires long exposure times, yet they still cannot reach the reduction achieved with a short, high-energy pulse. Additionally, the irradiated surface heats up significantly. In contrast, xenon lamps are very high-intensity sources that can easily reach this critical destruction threshold in milliseconds. The Xenon Steripulse-XL system produces the most effective form of germicidal UV light available.

With the increasing automation of cleanroom technology, the use of pulsed xenon UV lamps is also growing rapidly. The systems operate fully automatically and are integrated into the cleanroom setup already during development. Their millisecond exposure time is effective against all DNA-containing organisms, and the absence of chemical waste or gases makes this technology highly attractive for such applications.