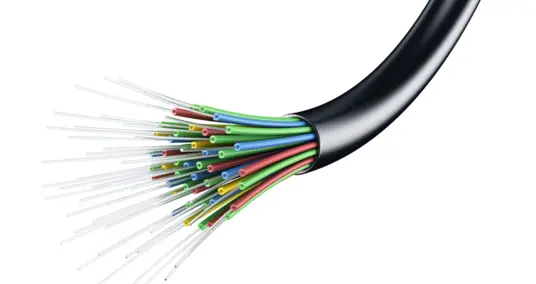

Fiber-optic systems are used in various disciplines for temperature measurement. Their strength lies especially in applications requiring a large number of measurement points, combined with a compact design and low thermal mass. A single fiber weighing just a few grams and with a diameter of only 150 µm can replace hundreds of sensors while simultaneously serving as the signal path. For many process engineering applications related to current Power-to-X technologies, they are therefore a good solution, as they provide a continuous temperature profile. Often, they are the only way to achieve the high data density needed to evaluate and optimize processes.

Basically, fiber-optic measurement systems consist of two components: a readout unit and the passive sensor fiber connected to it. The readout unit sends light into the fiber and analyzes the reflected or backscattered portions. A distinction is made between point-measuring and distributed-measuring systems. Point sensor solutions measure, like their electrical counterparts, at a defined measurement location. Distributed systems, on the other hand, are more interesting for chemical process engineering and related disciplines, as they can capture complete temperature profiles with dense measurement points.

No special sensors need to be embedded in the fiber. Instead, the light backscattered by the fiber material itself is evaluated to obtain the desired temperature information. This way, the entire fiber becomes the sensor. Two types can be distinguished: systems based on the Raman effect are suitable for measurement lengths of up to several tens of kilometers with measurement point spacing along the fiber of up to 25 centimeters.

The second type consists of systems based on the evaluation of Rayleigh scattering, which allow resolutions in the millimeter range. This means that practically every point along the glass fiber acts as a sensor. Conventional methods would require hundreds or thousands of conventional point sensors with associated wiring, resulting in often unacceptable installation and cost efforts.

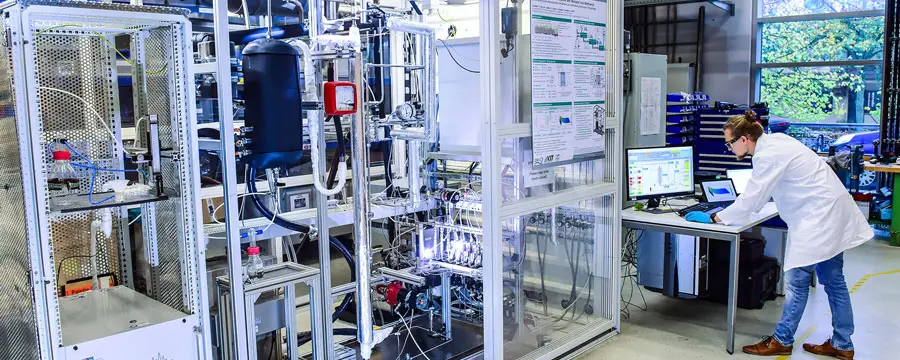

In the field of chemical process engineering, fiber-optic systems based on Rayleigh scattering are therefore gaining significant attention (see Image 1). For example, the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg, Germany, uses them in a mini-plant facility dedicated to methanol synthesis (see Image 2).

Mini-plant for advancing methanol synthesis

Methanol synthesis, as part of a Power-to-Liquid process, produces methanol from hydrogen and CO₂. The Fraunhofer facility serves to study synthesis at an industry-relevant scale. Research focuses include dynamic reactor operation and unconventional gas mixtures combining electrolytic hydrogen with CO₂-containing gas streams.

The mini-plant continuously converts hydrogen and CO₂ into methanol.

This reaction releases heat and produces water as a byproduct. However, several scientific questions remain open for large-scale industrial implementation in combination with biorefineries. For example, high CO₂ levels in the synthesis gas accelerate catalyst aging and reduce chemical conversion rates.

Additionally, fluctuations in hydrogen production from variable renewable energy sources, as well as variability in the CO₂ supply process, may require dynamic synthesis operation. Such dynamics are not yet considered in current processes, which mainly rely on conventionally sourced feedstocks.

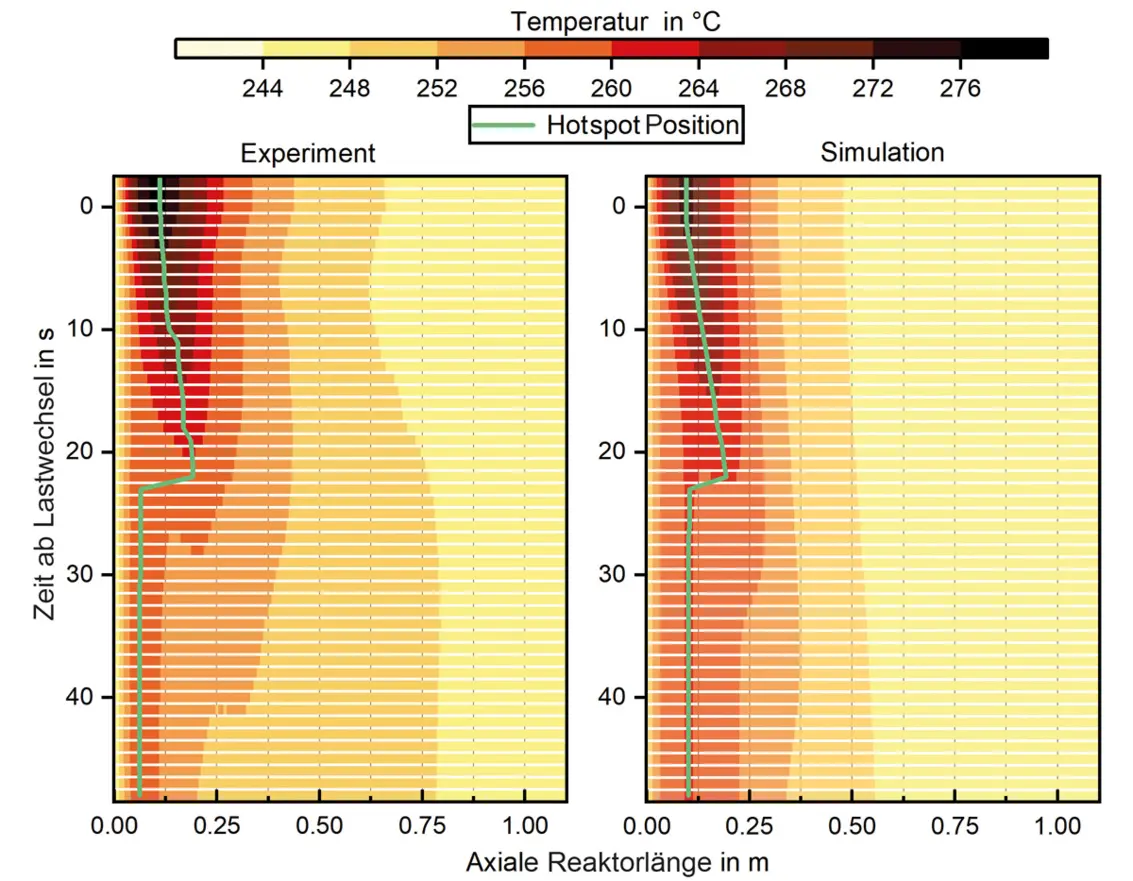

Real-time insights into reactor processes

By combining temperature measurement data with FT-IR, real-time statements about the reactor processes are possible every second. The analytics data can then be used to adjust model parameters for both steady-state and dynamic simulations. In the future, this will enable not only insights into reaction kinetics but also information about catalyst deactivation through long-term measurements.

Different operating points can be characterized very quickly, allowing even extensive parameter spaces to be processed efficiently. The insights gained are linked to the existing dynamic simulation platform of Fraunhofer ISE. This enables the study of load changes as they would occur in real industrial plants.

From this, valuable design data can be generated, helping to produce methanol from sustainable raw materials and renewable electricity, which can then be used in various applications as an energy storage medium, chemical, or fuel (additive).

Fiber-optic sensing uses Rayleigh scattering

In Rayleigh sensing, laser light is coupled into the glass fiber and the backscattered light from the fiber material is spatially scanned with high resolution using an optical measurement method. The result is a characteristic pattern along the fiber, called the fingerprint, which is different for each section but extremely stable and reproducible.

This is caused by local refractive index fluctuations and defects distributed statistically along the fiber. When external strain or temperature changes occur, this fingerprint is uniquely stretched or compressed, so changes in the local Rayleigh pattern can be converted into temperature or strain. Because every point along the fiber is sensitive to this effect, the entire fiber acts as a distributed sensor over its full length. The achievable spatial resolution is 1 millimeter. For a measurement length of, for example, 10 meters, this corresponds to 10,000 sensors. Using special fibers, the temperature measurement range spans approximately from -200 °C to +640 °C.

About the Fraunhofer Institute for Solar Energy Systems ISE

The Fraunhofer Institute for Solar Energy Systems ISE in Freiburg, with around 1,400 employees, is Europe’s largest solar research institute. Its research focuses on energy generation, distribution, storage, and utilization. In its business areas—photovoltaics, energy-efficient buildings, solar thermal power plants and industrial processes, hydrogen technologies, electrical energy storage, as well as power electronics, grids, and intelligent systems—the institute develops materials, components, systems, and processes. Additionally, it conducts analyses, studies, and consulting services, and offers testing and certification procedures.