In materials research, digital image correlation (DIC) is an established method for detecting deformations with high precision and without contact. This applies to tensile, compression, and bending tests as well as impact, fatigue, or pressure wave analyses, and more generally for detecting defects even beneath the sample surface. Nowadays, there are systems that use fluorescence instead of the usual speckle pattern applied on a base coating. This opens up new possibilities for material and component testing because shadows and reflections do not affect the measurement. Highly reflective materials or those that cannot be coated can also be tested, and even complex geometries or biological samples can be examined.

DIC systems offer many advantages over strain gauges or force sensors because they operate contactlessly and are very flexible. They can measure strains over a wide range, from microstrain to several hundred percent, and even small samples in the micrometer range can be characterized using microscope optics. High-speed cameras enable extremely high measurement rates, for example in automotive crash tests. The basic principle of DIC systems is simple to understand; it is based on analyzing image sequences to visualize deformations.

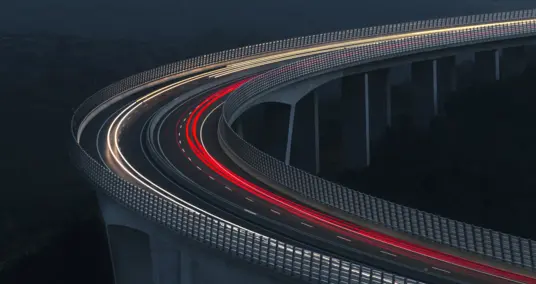

Typically, the test object is coated white and marked with a dark speckle pattern consisting of many randomly distributed dots (see image 1). During deformation, images of the component are captured using industrial cameras. For 2D measurements, one camera is sufficient; for capturing three-dimensional deformations, two cameras are required. The image correlation algorithms calculate how the speckle pattern shifts in the recorded image sequences. From the measured pixel coordinates of the pattern, the changes in the sample or component caused by deformation can then be determined with high accuracy.

Overcoming limitations with “photogenic patterning”

This digital image correlation approach has proven itself in countless applications over decades. However, the “normal” speckle pattern can’t always be used; there are cases where it fails due to the sample’s properties. For example, it reaches its limits where shadows occur on the object. Areas with notches or other complex geometries may receive little or no light, so the camera images show no meaningful changes in the speckle pattern. Textiles are a typical example. Highly reflective or wet surfaces can also pose challenges.

Polarized light can help in principle, but adjusting the filters is often quite complex. Also, not all surfaces can be coated because the coating might affect material properties or crack during deformation.

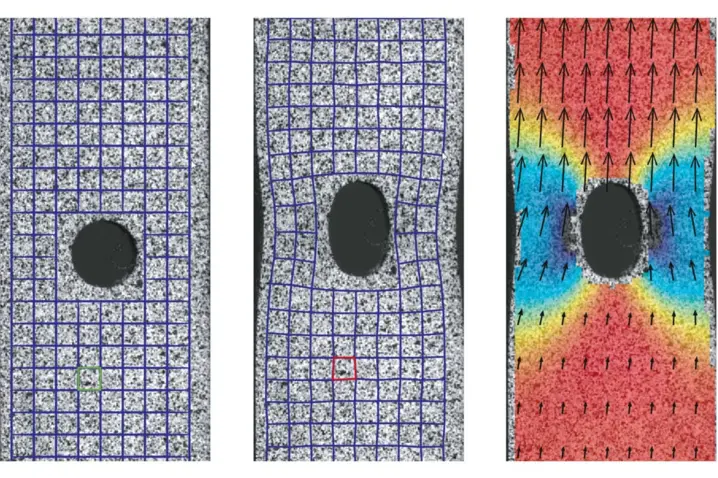

In such cases, there is now an alternative: “photogenic patterning,” developed by LaVision and offered by Polytec, avoids these issues even though it still uses the proven speckle pattern technique. On the surface of the test object, a speckle pattern made of fluorescent paint is applied, which generates its own light emission and is therefore called “photogenic” (see Image 2).

Fluorescence is the emission of light by a substance that absorbs light or other electromagnetic radiation. In most cases, the emitted light has a longer wavelength than the excitation light. This makes it possible to isolate the fluorescence pattern and analyze it using specially adapted digital image correlation algorithms. No base coating is required, and shadows caused by the surface texture or geometry of the sample are no longer critical. This allows the study of deformation behavior in materials where traditional digital image correlation previously faced limitations.

Versatile and biocompatible

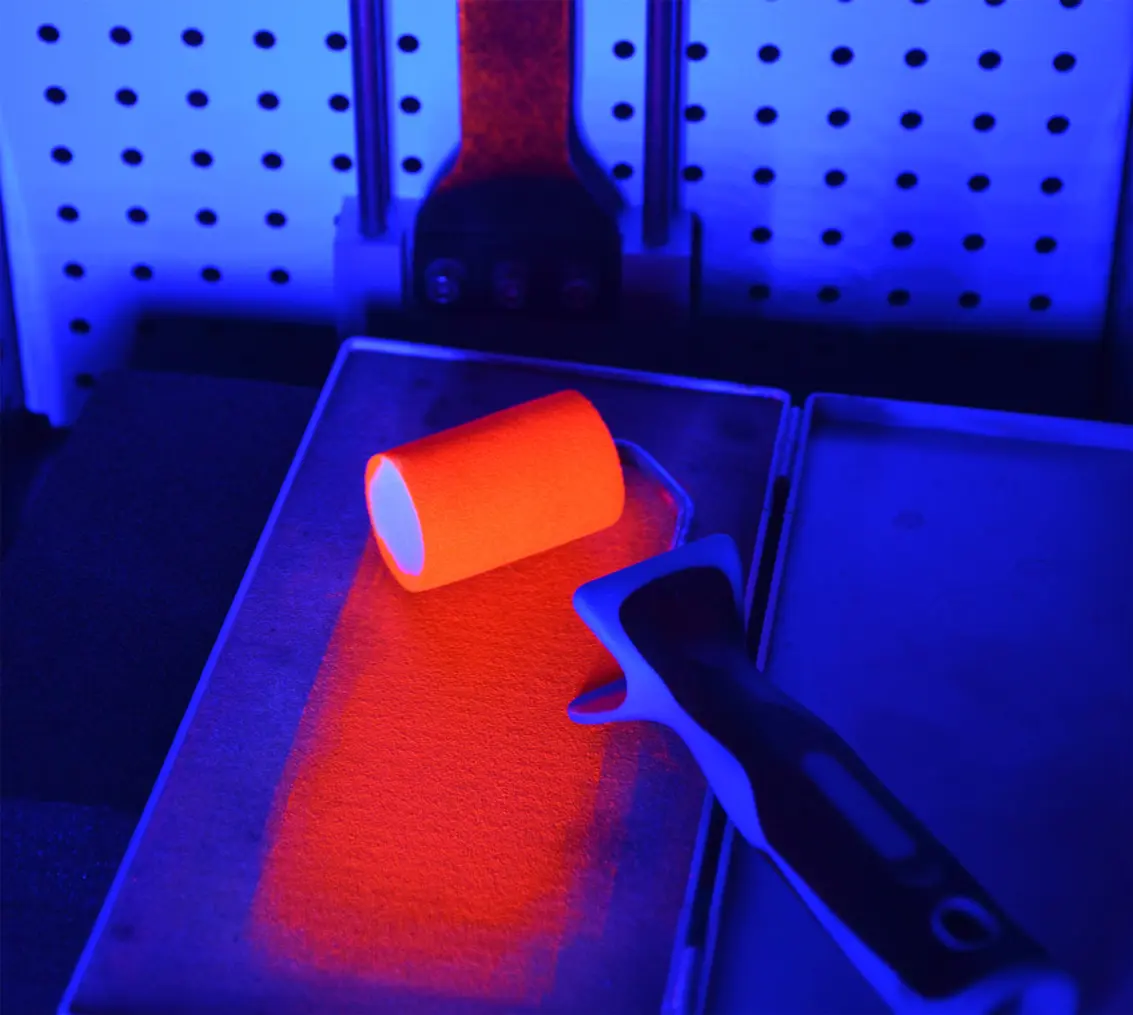

Fluorescent paints and the suitable application accessories come in many variants, making it possible to find an appropriate solution for nearly every surface. LaVision has extensive experience in this area, as fluorescence plays a role in many of their measurement techniques. The paints work on different substrates and can be easily wiped off after testing. Biocompatible paints, for example, are suitable for direct use on organic samples—even moist vocal cords can be measured this way (see Image 3). Combined with flow measurement, this allows precise tracking of movements. Even absorbent surfaces are suitable for “photogenic patterning,” with special chalks available for this purpose.

Polytec offers two DIC systems that can now also use fluorescent speckle patterns for two- or three-dimensional shape, stress, and deformation analysis: The StrainMaster Portable system (Figure 4) has a modular design. It consists of a controller, software, one or two cameras, lighting, and mechanics, and can also be expanded at a later date. All process steps involved in the measurement, from hardware control to data processing, validation, display, and data export, are integrated into the system. The software controls all process steps from recording to data export. The raw data collected is retained and can be reprocessed at any time. Important parameters such as resolution, field of view, strain range, and working distance depend on the lighting, cameras, and optics used and can be variably adapted to different applications.

The StrainMaster Compact digital image correlation system (Image 5) features a measurement head housed in a compact casing, containing two integrated USB3 cameras and a bright LED light source. The system’s advantages lie in its integrated design, easy and straightforward operation, and beginner-friendly price. Measurement rates of up to 150 Hz are possible. Four device variants with different resolutions and fields of view allow optimization tailored to the application. A complete system includes the measurement head, controller with display, mouse and keyboard, as well as the StrainMaster Compact software. This opens up new possibilities for digital image correlation, benefiting material testing across various fields.