The following article compares various forms of force excitation in order to determine the transfer admittances of mechanical systems using a gear wheel as an example. The objective is to analyze and assess the acoustic properties of technical structures, e.g. the drive train of an electric vehicle, in the higher frequency range. The experiments demonstrated that with a broadband piezoelectric force excitation the gathered measurement results become far more consistent, especially at high frequencies.

State of the art

As the use of electric drives in vehicles increases, new requirements for the acoustic properties of the overall drive train are arising. The conventional internal combustion engine generates a relatively high noise level, which covers certain disturbing noises, e.g. the “gearbox whine”. This “auditory masking” of the internal combustion engine does not apply to electric drives, whereby fractions in the higher frequency range come to the fore. Current research and development activities therefore focus on reducing these acoustic properties.

The transfer response of the components of the drive train is described by “network models” [1] at Fraunhofer IWU. One basis for this approach is the description of the individual components, e.g. a gear wheel, by way of frequency-dependent transfer functions. This is provided by means of harmonic force excitation of the components and measurement of the structural response using 3D laser scanning vibrometry.

Force excitation in the interesting frequency range (up to 20 kHz) represents a challenge to the existing excitation technology, especially in the case of large structures. Electrodynamic shakers or pulse hammers are the state of the art. Often, the applied forces are not high enough to obtain consistent measurement results (absolute value and phase), particularly at higher frequencies (> 5 kHz). A procedure for broadband force excitation using a piezoelectric modal exciter (dm 2) and a comparison with a conventional exciter (Brüel&Kjær 4810) is described in this article.

Measurement setup

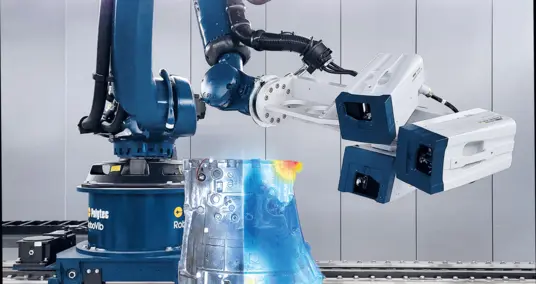

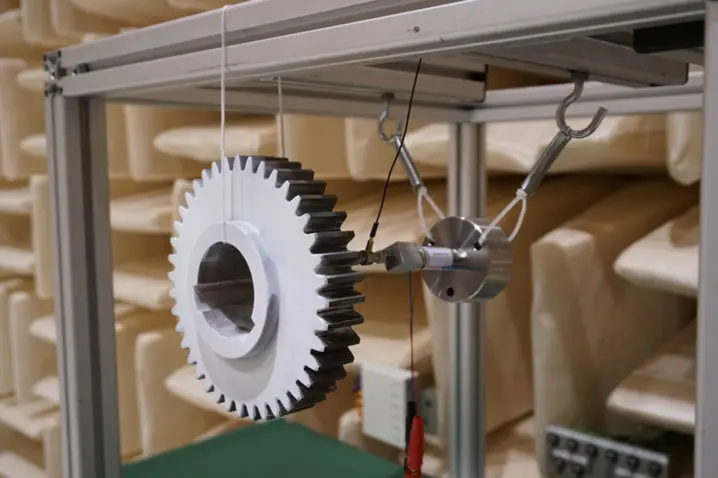

The two shakers were compared under free-free boundary conditions, whereby the respective exciter and the test object were suspended in a rack by means of springs and elastic decoupling elements. The rigid coupling between shaker and test object was realized via a load cell (Brüel&Kjær, type 8203). Figure 1 shows the described test setup with the piezoshaker dm 2.

The system response was acquired by means of a Polytec PSV-3D Scanning Vibrometer. A periodic chirp was used as an excitation signal, whereby the specified excitation and evaluation frequency range was 3.5 to 16 kHz (bandwidth 20 kHz, 12800 FFT lines).

Results

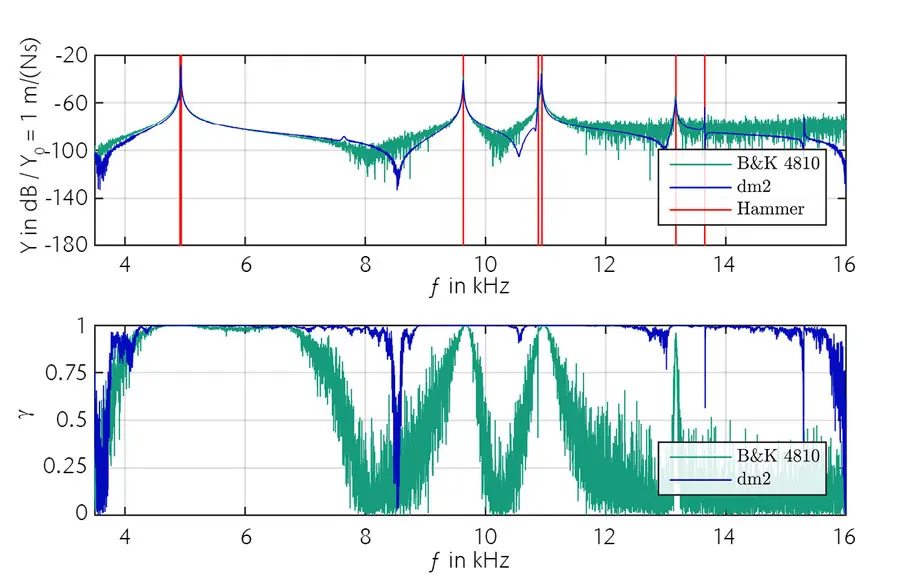

Figure 2 shows the comparison of the transfer admittances of the individual measurement points diametrically opposite the point of force application (cf. figure 1). The natural frequencies (marked in red) were determined in a preceding experimental modal analysis using an automated pulse hammer. In addition, the associated coherence profiles are shown in the bottom diagram in figure 2.

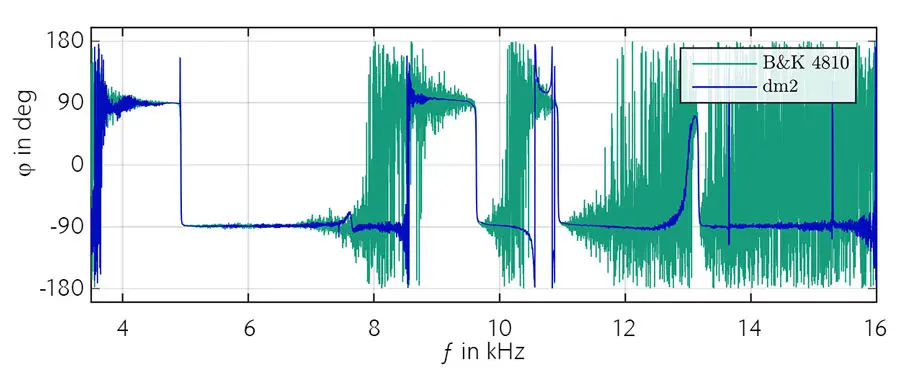

It is apparent that the amount of energy that can be applied to the system with the shaker B&K 4810 above approx. 7 kHz is not high enough to obtain a satisfactory signal-to-noise ratio, as illustrated by the respective coherence and the clearly identifiable noise levels in the course of the transfer admittance from 7 kHz. When using the dm 2, it is apparent that this is suitable for acquisition of the system responses in the higher frequency range. Clean acquisition of the transmission functions is possible due to the significantly higher energy input, which is also illustrated by the comparison of the phase frequency responses shown in figure 3.

Summary

Various force exciters were compared in this article, in order to measure the transfer admittances of gear wheels. The objective was to find a suitable excitation method in the higher frequency range, in order to enable e.g. the description of the acoustic properties of technical structures on the basis of metrologically acquired transmission functions. It was demonstrated that significantly more consistent measurement results can be obtained with broadband piezoelectric force excitation, especially at high frequencies.

Further work will include investigation of the connection of the force exciter and extension of the frequency range to lower frequencies. In addition, future work will focus on the acquisition of rotational degrees of freedom in the higher frequency range.

References

[1] Bräunig, J. et al.: Options for the vibro-acoustic structure investigation of a wheel body of a tooth system.

In: ant journal, Antriebstechnik 53 (2 2014), p. 3-9.